عجلة مدمجة ثلاثية الأضلاع لـ MTB مع معالجة CNC ومعالجة السطح

Magnesium alloy die-casting rigid fork for bike

أجزاء ومكونات صب سبائك المغنيسيوم للدراجة الإلكترونية

Magnesium alloy die-casting wheel for ebike

منتجات مسبك مخصصة أجزاء صب يموت عالية الدقة للإطار المتكامل للدراجة الإلكترونية

منتجات مسبك مخصصة مكونات الدراجة الإلكترونية عجلة سبائك المغنيسيوم

غطاء محرك السيارة الكهربائية المصبوب من سبائك المغنيسيوم في المنتصف

إطار الدراجة الجبلية Magensium

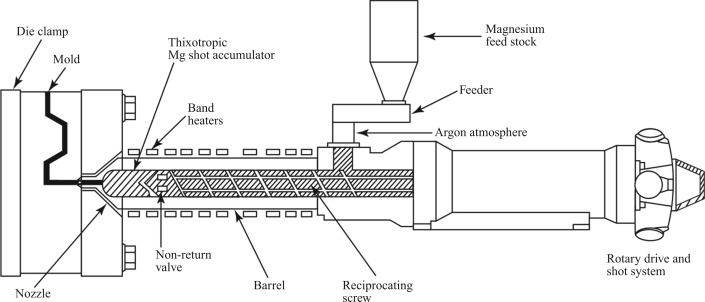

Magnesium alloy Thixomolding parts for oxygen suction machine housing

فرامل معدنية مسبوكة من سبائك المنغسيوم

Mangensium alloy die-casting Thixomolding metal parts

أجزاء ومكونات صب سبائك المغنيسيوم للدراجة الإلكترونية

سبائك المغنيسيوم Thixomolding السلطة الخليط الإسكان

Mangensium alloy die-casting Thixomolding metal parts

Mangensium alloy die-casting Thixomolding helmet

سبائك المغنيسيوم Thixomolding السلطة الخليط الإسكان

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com