In competing with aluminium alloys as structural materials, magnesium alloys have the advantages of low density, high strength ratio, better electromagnetic shielding properties and castability. These result in the preferential use of magnesium alloys in 3C components(Computer, Communication and Consumer product) where lightweight , heat dissipation, electromagnetic shielding is critical.also have extremely broad applications in the fields of automotive, aerospace,outdoor sports and so on.

With the high integration in 3C , removing the excessive heat produced during the operation of electronic components and heat exchangers, which causes the components to fail as a result of overheating or deformation, becomes more urgent. The demand for materials with both excellent heat dissipation and mechanical properties is increasing rapidly. Selecting materials with appropriate thermal conductivity is very important for achieving the best performance of components.

Mg alloys exhibit great potential as heat dissipation materials owing to their smaller heat capacity and better heat dissipation effects than those of Al alloys. Over the past decades, there have been some efforts devoting to enhancing the thermal conductivity of Mg alloys with a clear understanding of the fundamental heat transfer at the micro, nano and even molecular scales.

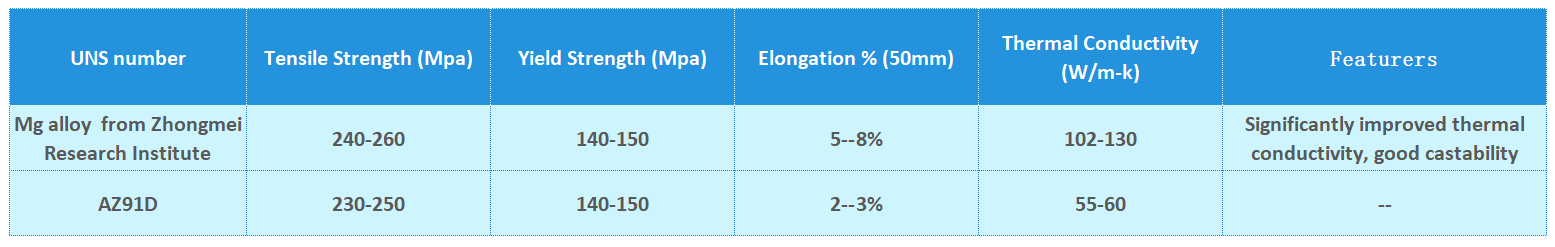

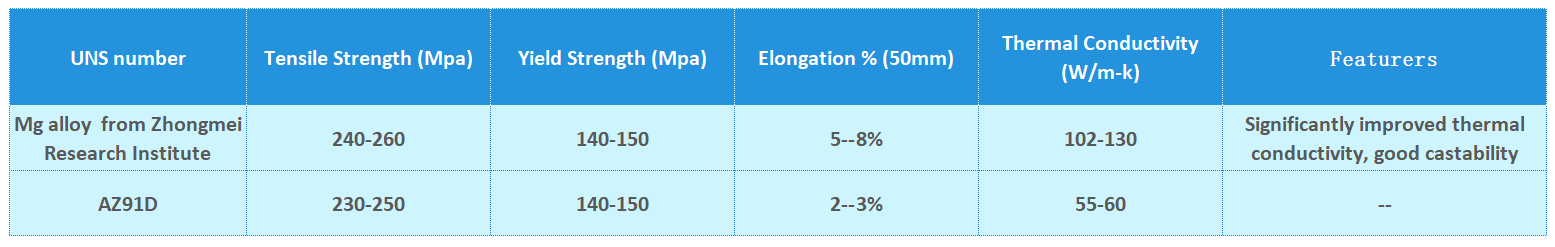

Aiming to develop a Mg alloys that can provide significantly improved thermal conductivity in comparison to the commonly used AZ91D magnesium alloys, Zhongmei built Research Institute of Magnesium Alloy Materials jointly with the global leading expert, Prof. Pan Fusheng of Chongqing University and his team.

The Research Instittue keep doing experiments & testing , has made considerable achievements

Key Benefits

Improved thermal conductivity of magnesium alloys – critical in applications specifically for increasing the capacity of heat exchange and heat sink of engineering components.

The improved thermal conductivity can reduce the working temperatures of final products and therefore increase the energy efficiency and product life.

Applications

Electric automotive industry

3C components(Computer, Communication and Consumer product)

Communication base station components and other heat sinks

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com