Magnesium alloy bike parts & componenets for kid’s push bike

Magnesium alloy rigid fork for bicycle -customized die casting metal parts

Integrisani točak sa 3 kraka za MTB sa CNC obradom i obradom površine

Okvir za brdski bicikl od magnezijuma

OEM high pressure die casting magnesium alloy frame for bicycle

Prilagođeni proizvodi za ljevanje, visoko precizni dijelovi za livenje pod pritiskom za integrirani okvir e-bicikla

Kruta viljuška od legure magnezijuma za bicikl

Magnesium alloy die-casting wheel for ebike

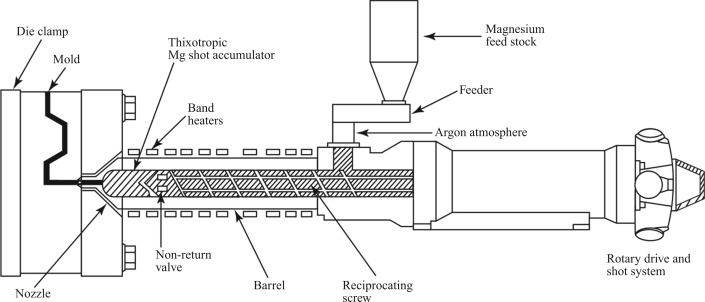

Lijevanje pod tlakom od legure mangenzija Thixomolding metalne kočnice

Dijelovi za oblikovanje kućišta mašine za usisavanje kiseonika od legure magnezijuma

Lijevanje pod tlakom od legure mangenzija Tiksomoblikovanje metalnih dijelova

Lijevanje pod tlakom od legure mangenzija Tiksomoblikovanje metalnih dijelova

Legura magnezijuma Thixomolding Power Batter Kućište

Dijelovi i komponente za livenje pod pritiskom od legure magnezija za e-bicikle

Legura magnezijuma Thixomolding Power Batter Kućište

Mangensium alloy die-casting Thixomolding helmet

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com