Do you know about magnesium alloys? Have you ever used magnesium alloy products? We are a Magnesium touch-shaped UAV shell production company, we are the leading company in the industry, and we can provide you with the best quality products and services. We can also offer you a variety of housing for any application. We are always innovating and expanding our products to provide the best experience for our customers.

What is thixotropy

Thixoforming is an innovative and environmentally friendly magnesium forming method.

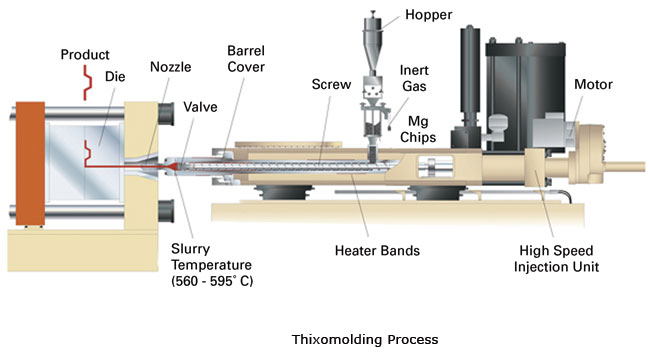

Thixotropic molding is the injection molding of semi-molten (thixotropic) magnesium alloys.

Magnesium chips made by cutting magnesium alloys are heated in the cylinder of a molding machine and injection-molded into a mold as-is without exposure to the atmosphere.

Advantages of magnesium thixotropy

Compared to engineering plastics and die casting, magnesium thermoforming produces thinner, lighter, stronger parts. The process also offers many cost advantages over other production methods. These advantages include higher product yield, longer tool life, lower cost of ownership, and process consistency.

Other benefits of magnesium:

High strength to weight ratio

good machinability

good heat transfer characteristics

non-magnetic

Higher temperature applications than plastics

Easier to recycle than plastic

Excellent damping capacity

As a Magnesium touch-shaped UAV shell production company, we have always been committed to providing customers with high-quality products and services. To better meet the needs of customers, we constantly improve our production technology and equipment.

Our company has a wide range of products, including magnesium thixotropic drone casings, which are widely used in various fields. We have a team of professional technicians and workers who have many years of experience in manufacturing magnesium thixotropic drone casings. We have strict quality control procedures to ensure our products meet the highest standards.

We are confident that our products will meet your needs and expectations. If you have any questions or comments, please feel free to contact us. We look forward to serving you in the future.

-

- Dijelovi i komponente za livenje pod pritiskom od legure magnezija za e-bicikle

-

- 2022 Veleprodaja Hot Sale Dijelovi za bicikle od legure magnezija Dječji bicikl bez pedala Balance Bicikl za djecu u više boja na raspolaganju

-

- OEM proizvođač livenja pod pritiskom proizvodi automatsku instrument tablu od legure magnezija

-

- Dijelovi za tiksom kalup od magnezija Kućište UAV-a

-

- OEM die casting service metal components of macbook middle

-

- Dijelovi za tiksom kalupljenje po narudžbi UAV komponente sa CNC obradom i površinskom obradom

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com