Magnesium alloys are alloys composed of magnesium and other elements. The main alloying elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium. Magnesium alloys are light metal structural materials and are known as green engineering structural materials in the 21st century. It has very good application properties. It has the advantages of high specific strength, high specific stiffness, good shock absorption, large impact load capacity, excellent electromagnetic shielding performance, no biological toxicity, good resistance to organic substances and alkali corrosion, and abundant resources. Currently used in auto parts.

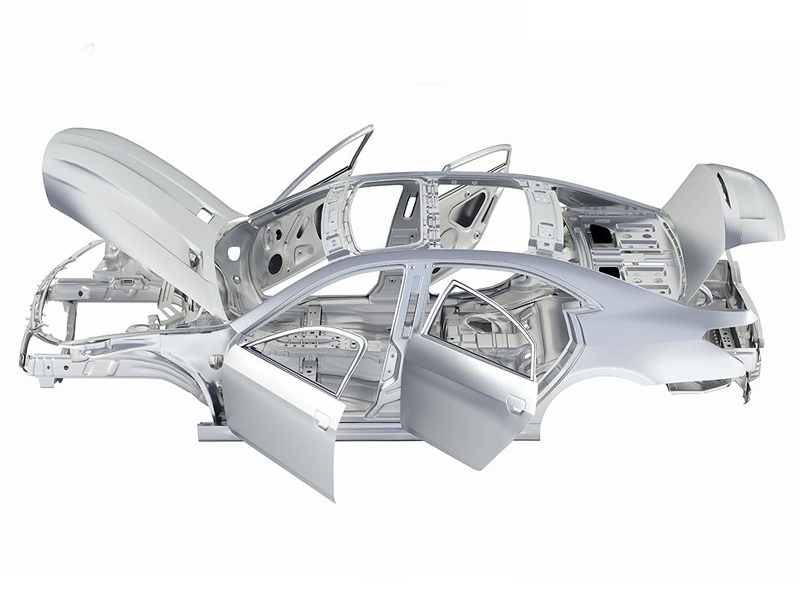

1. Application of magnesium alloys in automobiles Automobile magnesium alloys have a good weight reduction effect. On the premise of ensuring the strength and rigidity of auto parts, it is one of the important ways to realize the lightweight of automobiles to choose the lightest materials as much as possible. Magnesium alloy is the lighter material among the commonly used metal structural materials, with abundant reserves. In order to improve its fuel economy and controllability, it has become the preferred material for vehicle weight reduction.

The advantages of magnesium alloy die-casting auto parts transfer case used in automobiles: light weight, density is only 2/3 of aluminum alloy; rigidity can replace aluminum alloy and steel parts; good casting performance, stable size, easy processing, scrap rate Low; it has a good damping coefficient, and the amount of vibration reduction is greater than that of aluminum alloy and cast iron. It can reduce noise when used in shell manufacturing, and can reduce vibration when used in seat and rim manufacturing, thereby improving the safety and comfort of automobiles; it has good anti-electromagnetic interference and shielding ability, reduces noise, and has little environmental pollution. reuse.

2. Typical parts of magnesium alloys

With the in-depth implementation of the “magnesium alloy application development and industrialization” project, my country’s automobile industry has benefited a lot from it, and the effect is obvious. Many businesses have come a long way. The magnesium alloy auto parts that have been developed and applied can be roughly divided into two categories:

1.Housing: such as clutch housing, valve cover, valve plate, transmission housing, instrument panel, crankcase, engine front cover, cylinder box, instrument panel, filter housing, etc.

2. Brackets: such as steering brackets, steering wheel, lamp brackets, brakes, clutch pedal brackets, brake brackets, seat frames, mirror brackets, distribution brackets and wheel hubs.

With the development of magnesium alloy auto parts, the application of magnesium alloys in automobiles has the following characteristics: transition from small parts to large parts, transition from simple parts to complex parts, transition from simple stress parts to parts that meet special performance requirements, From component composition to integrated design.

According to research, approximately 75% of fuel consumption is related to vehicle mass. Reducing vehicle mass can effectively reduce fuel consumption and emissions. Reducing overall vehicle mass also significantly reduces power transmission loads for better handling at lower towing loads.

Magnesium alloys are the first choice for automotive applications. Welcome to contact us for more applications about magnesium alloys.

-

- Dijelovi ljevaonice magnezija Stup upravljača

-

- Ultralagana ovjesna viljuška za MTB

-

- Dijelovi za tiksom kalupljenje po narudžbi UAV komponente sa CNC obradom i površinskom obradom

-

- OEM die-casting components & parts

-

- Magnesium alloy die-casting Auto parts RDM housing

-

- OEM die casting service metal components of macbook middle

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com