In today’s competitive business environment, companies are constantly striving to develop innovative and high-quality products to meet the ever-changing demands of consumers. However, product development can be a complex and time-consuming process that requires careful planning, coordination, and testing. One strategy that has proven to be highly effective in streamlining this process is prototyping.

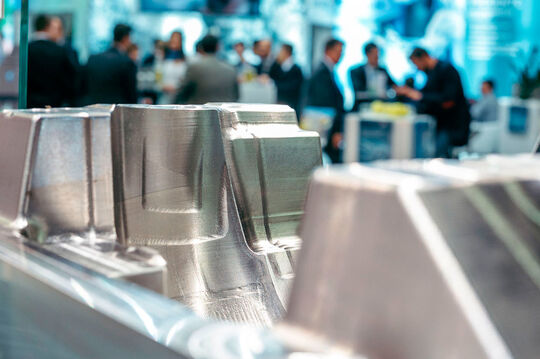

Prototyping is the process of creating a preliminary version or model of a product prior to its mass production. It serves as a tangible representation of the final product, allowing designers, engineers, and stakeholders to evaluate its functionality, aesthetics, and performance. By creating a prototype, companies can identify and resolve design flaws, improve user experience, and make informed decisions before investing heavily in mass production.

One of the primary advantages of prototyping is its ability to foster effective communication between different teams involved in the product development process. Designers can visually convey their ideas and concepts to engineers, who can then assess the feasibility of implementing these ideas. By facilitating collaboration, prototyping ensures that all stakeholders are on the same page and working towards a common goal.

Moreover, prototyping enables companies to gather valuable feedback from potential users and customers. By showcasing a prototype to focus groups or conducting usability testing, companies can gain insights into how the product is perceived and used. This early feedback is invaluable as it allows companies to make necessary adjustments or enhancements to meet user expectations and preferences. By involving users in the development process from the beginning, companies can create products that truly resonate with their target audience.

Another significant benefit of prototyping is its cost-effectiveness. Developing a prototype is generally less expensive than directly investing in mass production. It allows companies to validate their ideas and concepts without incurring significant manufacturing costs. Moreover, by identifying design flaws and making improvements early on, companies can avoid costly mistakes in the later stages of product development. This ultimately saves time and money and enhances overall efficiency.

Prototyping also plays a crucial role in accelerating the product development timeline. Traditionally, product development involved a linear process of design, development, testing, and production. This sequential approach was time-consuming and often resulted in delayed product launches. With prototyping, companies can adopt an iterative approach, continuously refining and iterating on the design based on user feedback. This agile methodology allows for faster development cycles and shorter time-to-market, giving companies a competitive edge in today’s fast-paced business landscape.

However, it is essential to note that prototyping is not without its challenges. Developing a prototype requires expertise in various areas, including design, engineering, and manufacturing. Companies need to invest in skilled professionals and advanced technologies to create accurate and functional prototypes. Furthermore, managing multiple iterations of prototypes can be time-consuming and resource-intensive. Therefore, companies need to strike a balance between the number of iterations and the resources invested in prototyping.

Prototyping is a crucial step in efficient product development. It enables effective communication, gathers valuable feedback, reduces costs, and accelerates the development timeline. By investing in prototyping, companies can ensure that their products meet user expectations, achieve market success, and stay ahead of the competition. In today\’s rapidly evolving business landscape, prototyping has become an indispensable tool for companies striving for innovation and excellence.

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com