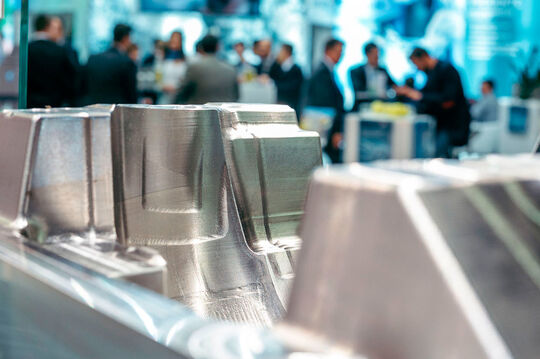

Aluminum casting molds play a pivotal role in the intricate world of metal casting, providing the foundation for creating precise and complex shapes. This article delves into the art and science behind aluminum casting molds, exploring their significance, the design and manufacturing processes, and the innovations shaping this dynamic field.

Aluminum casting molds serve as the backbone of the metal casting industry, enabling the production of a wide range of components used in diverse applications. From automotive parts to aerospace components, the versatility of aluminum molds is unmatched. This section introduces the critical role these molds play in the manufacturing process, setting the stage for an in-depth exploration.

The Design and Manufacturing Process of Aluminum Casting Molds

Creating an aluminum casting mold is a meticulous process that requires a harmonious blend of design expertise and precision manufacturing. This section walks through the key steps involved in designing and producing these molds. From the initial concept and material selection to the intricate details of mold creation, readers gain insights into the intricate journey of bringing an aluminum casting mold to life.

Innovations Shaping Aluminum Casting Mold Technology

The landscape of aluminum casting mold technology is continually evolving, driven by innovation and the quest for enhanced efficiency. This part of the article explores the latest advancements in mold design and manufacturing processes. Topics include the integration of computer-aided design (CAD), simulation technologies, and the adoption of novel materials, shedding light on how these innovations are revolutionizing the industry.

Challenges and Considerations in Aluminum Casting Mold Production

While aluminum casting molds offer unparalleled advantages, they are not without challenges. This section discusses common hurdles faced in the production process, such as the need for precision, challenges in cooling and solidification, and the impact of mold wear. Addressing these considerations is essential for ensuring the quality and longevity of aluminum casting molds.

The article summarizes the key takeaways, emphasizing the pivotal role of aluminum casting molds in modern manufacturing. It underscores the delicate balance between art and science in mold design and manufacturing, showcasing how advancements in technology continue to shape the future of this critical industry.

-

- Customized foundry products e-bike components magnesium alloy wheel

-

- Magnesium Aluminium alloy die casting parts Chain cover for automotive

-

- Magnesium foundry parts Steering column

-

- High precision magnesium thixomolding components laptop housing cover A

-

- Magnesium alloy die-casting Auto parts headlight frame

-

- Magnesium alloy die-casting Auto parts RDM housing

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com