Die casting is a manufacturing process that involves the production of complex metal parts by injecting molten metal into a mold. Creating a die casting mold is an essential step in the die casting process. It is the foundation of the entire process, and it determines the accuracy, quality, and consistency of the final product.

The process of creating a die casting mold requires careful planning, design, and execution. It involves several stages, including mold design, mold fabrication, mold testing, and mold maintenance. In this article, we will discuss the steps involved in creating a die casting mold.

Step 1: Mold Design

The first step in creating a die casting mold is mold design. This involves designing the mold cavity and the gating system. The mold cavity is the space in the mold where the molten metal is injected to form the final product. The gating system is the network of channels and gates that deliver the molten metal to the mold cavity.

The mold design process starts with an understanding of the product design and the requirements of the final product. The mold designer will consider factors such as the size, shape, and complexity of the product, as well as the material used for the product.

Step 2: Mold Fabrication

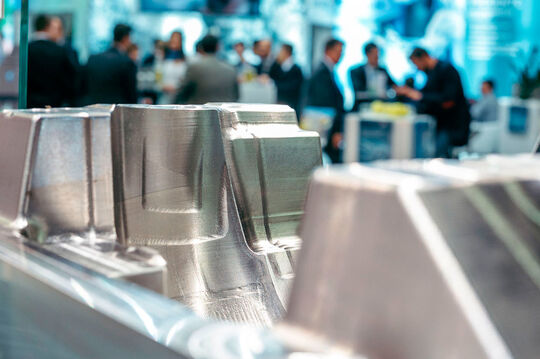

Once the mold design is complete, the next step is mold fabrication. This involves creating the mold based on the design specifications. The mold can be made from a variety of materials, including steel, aluminum, and copper alloys.

The mold fabrication process involves several steps, including cutting the mold blocks, milling the mold cavities, drilling gating and cooling channels, and polishing the mold surfaces. The mold maker will use precision equipment and techniques to ensure that the mold is accurate and precise.

Step 3: Mold Testing

After the mold is fabricated, the next step is mold testing. Mold testing is performed to ensure that the mold is functional and produces high-quality parts. The testing process involves injecting molten metal into the mold and evaluating the quality and accuracy of the final product.

The testing process may reveal issues with the mold design or fabrication that need to be addressed. The mold maker may need to make adjustments to the mold to ensure that it produces high-quality parts consistently.

Step 4: Mold Maintenance

Once the mold is in production, it is important to perform regular maintenance to ensure that it continues to produce high-quality parts. Mold maintenance involves cleaning the mold, inspecting it for wear or damage, and making any necessary repairs or adjustments.

Regular maintenance can help extend the life of the mold and improve the quality and consistency of the final product. It is important to perform maintenance on a regular basis to avoid downtime and ensure that the manufacturing process runs smoothly.

In conclusion, creating a die casting mold is a complex and important process that requires careful planning, design, fabrication, testing, and maintenance. The quality and accuracy of the mold are essential to the quality and consistency of the final product. By following these steps, manufacturers can create high-quality die casting molds that produce accurate and consistent parts.

-

- Magnesium alloy foundry parts bicycle wheel with CNC machining & surface finishing

-

- Magnesium alloy die-casting Auto parts Front bumper Anti-collision beam

-

- Custom-made metal parts macbook middle board produced

-

- Oblíbené dětské sportovní kolo Vysoce kvalitní dětské balanční kolo Dětské kolo

-

- Díly a komponenty ze slitiny hořčíku pro elektrokola

-

- OEM komponenty tlakového lití pro automobilový rám sedadla

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com