Odlévané kolo z hořčíkové slitiny pro ebike

Díly a komponenty ze slitiny hořčíku pro elektrokola

Díly a komponenty na kolo z hořčíkové slitiny pro dětská kola

Zakázkové slévárenské produkty komponenty elektrokol kola z hořčíkové slitiny

Pevná vidlice z hořčíkové slitiny pro odlévání kovových dílů podle požadavků zákazníka

Magensiový rám horského kola

Kryt motoru elektrického vozidla z tlakového lití z hořčíkové slitiny uprostřed

Slévárenské díly z hořčíkové slitiny rám jízdního kola CNC obrábění a povrchová úprava

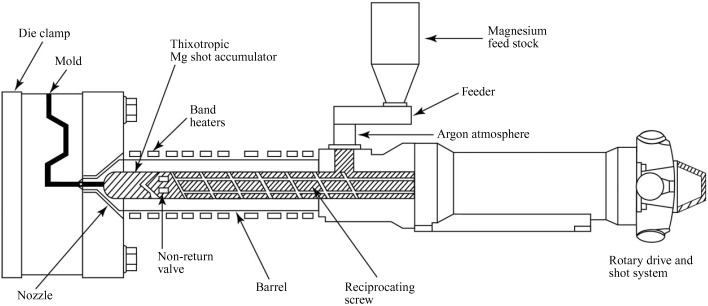

Tlakové lití z mangenové slitiny Tixomouldování kovových dílů

Přilba Thixomolding z tlakového lití z mangenové slitiny

Tlakové lití z mangenové slitiny Tixomouldovací kovové brzdy

Slitina hořčíku Thixomolding pouzdro na šlehač

Tlakové lití z mangenové slitiny Tixomouldování kovových dílů

Slitina hořčíku Thixomolding pouzdro na šlehač

Díly a komponenty ze slitiny hořčíku pro elektrokola

Slitina hořčíku Tixomulační díly pro skříň stroje na odsávání kyslíku

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com