Kundenspezifische Gießereiprodukte hochpräzise Druckgussteile für integrierte E-Bike-Rahmen

OEM-Rahmen aus Hochdruckguss-Magnesiumlegierung für Fahrräder

Druckguss-Elektrofahrzeug-Mittelmotorgehäuse aus Magnesiumlegierung

Starrgabel aus Druckguss aus Magnesiumlegierung für Fahrräder

Magensium-Mountainbike-Rahmen

Starrgabel aus Magnesiumlegierung für Fahrräder - kundenspezifische Druckguss-Metallteile

Fahrradteile und Komponenten aus Magnesiumlegierung für Laufräder für Kinder

Druckgussrad aus Magnesiumlegierung für E-Bikes

Druckgussteile und -komponenten aus Magnesiumlegierung für E-Bikes

Thixomolding-Helm aus Mangansium-Druckguss

Druckguss-Thixomolding-Metallhalterungen aus Mangansiumlegierung

Magnesiumlegierung Thixomolding-Power-Batter-Gehäuse

Magnesiumlegierung Thixomolding-Power-Batter-Gehäuse

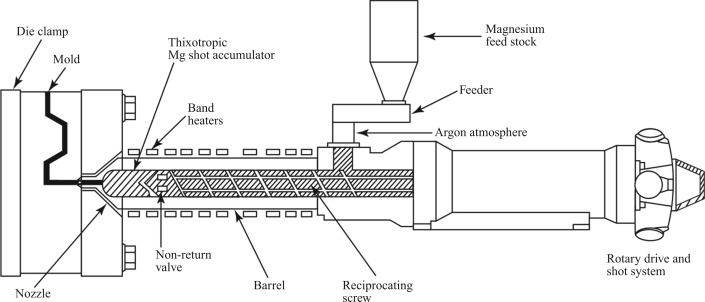

Druckgussteile aus Mangansiumlegierung Thixomolding-Metallteile

Druckgussteile aus Mangansiumlegierung Thixomolding-Metallteile

Thixomolding-Teile aus Magnesiumlegierung für Sauerstoff-Saugmaschinengehäuse

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com