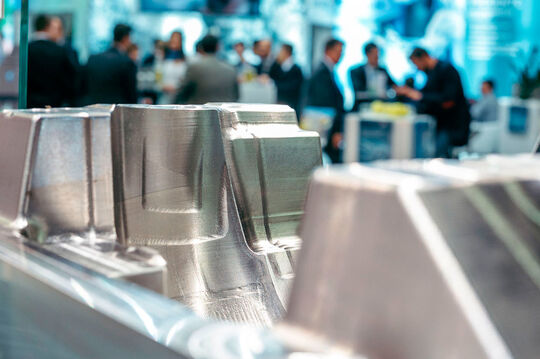

Die casting is a highly efficient manufacturing process that involves injecting molten metal into a mold cavity under high pressure. This technique is widely used in various industries to produce high-quality products with excellent dimensional accuracy and surface finish. As a leader in the field of die casting, our company is committed to delivering excellence in engineering and manufacturing.

One of the key factors that sets us apart from our competitors is our relentless focus on quality. We understand that our customers rely on us to provide them with die casting products that meet their exact specifications. To ensure this, we have implemented a rigorous quality control system that covers every stage of the manufacturing process.

At the initial stage, our team of experienced engineers works closely with the customers to understand their requirements and design the mold accordingly. We utilize advanced computer-aided design (CAD) software to create precise and detailed mold designs. This enables us to eliminate any potential design flaws and optimize the performance of the final product.

Once the mold is ready, we employ state-of-the-art die casting machines to produce the components. These machines are equipped with advanced automation features that enable us to achieve consistent and repeatable results. The high-pressure injection system ensures that the molten metal fills the mold cavity uniformly, resulting in products with excellent dimensional accuracy.

To further enhance the quality of our die casting products, we have invested in advanced inspection equipment. Our dedicated quality control team conducts thorough inspections at every stage of the manufacturing process to identify any deviations from the specifications. This includes dimensional checks, surface finish evaluations, and material quality assessments. By adhering to strict quality control standards, we ensure that only products meeting the highest standards leave our facility.

In addition to our focus on quality, we are also committed to continuous improvement and innovation. We strive to stay at the forefront of the industry by investing in the latest technology and techniques. This allows us to provide our customers with cutting-edge die casting solutions that meet their evolving needs.

Furthermore, we understand the importance of sustainability in today’s world. Our manufacturing processes are designed to minimize waste and optimize energy efficiency. We utilize recycled materials whenever possible and employ environmentally friendly practices throughout our operations. By doing so, we not only contribute to a greener planet but also help our customers meet their sustainability goals.

Our dedication to excellence in engineering and manufacturing has earned us a reputation as a trusted partner in the industry. We have successfully served a wide range of customers across various sectors, including automotive, aerospace, and electronics. Our ability to deliver high-quality die casting products on time and within budget has made us the preferred choice for many leading companies.

Our company is committed to delivering excellence in engineering and manufacturing high-quality die casting products. Through our focus on quality, continuous improvement, and sustainability, we strive to exceed our customers’ expectations. With our state-of-the-art facilities, experienced team, and cutting-edge technology, we are well-equipped to meet the diverse needs of our customers and contribute to their success.

-

- CNC-bearbeitete Teile und Komponenten

-

- Elektrofahrrad Magnesiumlegierung 12 Zoll integriertes Rad 36v10ah Elektromoped

-

- Fahrradteile und Komponenten aus Magnesiumlegierung für Laufräder für Kinder

-

- Druckgussrad aus Magnesiumlegierung für E-Bikes

-

- Mittelsteuerungsabdeckung aus Druckguss-Autoteile aus Magnesiumlegierung

-

- Magnesiumlegierung Thixomolding-Power-Batter-Gehäuse

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com