Im Wettbewerb mit Aluminiumlegierungen als Konstruktionsmaterialien haben Magnesiumlegierungen die Vorteile einer geringen Dichte, eines hohen Festigkeitsverhältnisses, besserer elektromagnetischer Abschirmeigenschaften und Gießbarkeit. Dies führt zur bevorzugten Verwendung von Magnesiumlegierungen in 3K-Komponenten (Computer-, Kommunikations- und Verbraucherprodukte), bei denen geringes Gewicht, Wärmeableitung und elektromagnetische Abschirmung entscheidend sind. Sie haben auch extrem breite Anwendungen in den Bereichen Automobil, Luft- und Raumfahrt, Outdoor-Sportarten usw.

Mit der hohen Integration in 3C wird es dringlicher, die beim Betrieb von elektronischen Bauteilen und Wärmetauschern entstehende übermäßige Wärme abzuführen, die durch Überhitzung oder Verformung zum Ausfall der Bauteile führt. Die Nachfrage nach Materialien mit hervorragender Wärmeableitung und mechanischen Eigenschaften steigt rasant. Die Auswahl von Materialien mit geeigneter Wärmeleitfähigkeit ist sehr wichtig, um die beste Leistung von Komponenten zu erzielen.

Mg-Legierungen weisen aufgrund ihrer geringeren Wärmekapazität und besseren Wärmeableitungswirkung als Al-Legierungen ein großes Potenzial als Wärmeableitungsmaterialien auf. In den letzten Jahrzehnten wurden einige Anstrengungen unternommen, um die Wärmeleitfähigkeit von Mg-Legierungen mit einem klaren Verständnis der grundlegenden Wärmeübertragung auf Mikro-, Nano- und sogar molekularer Ebene zu verbessern.

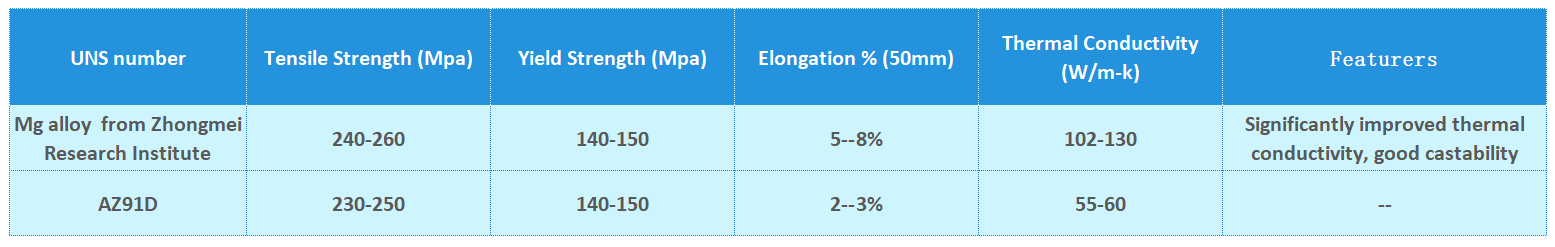

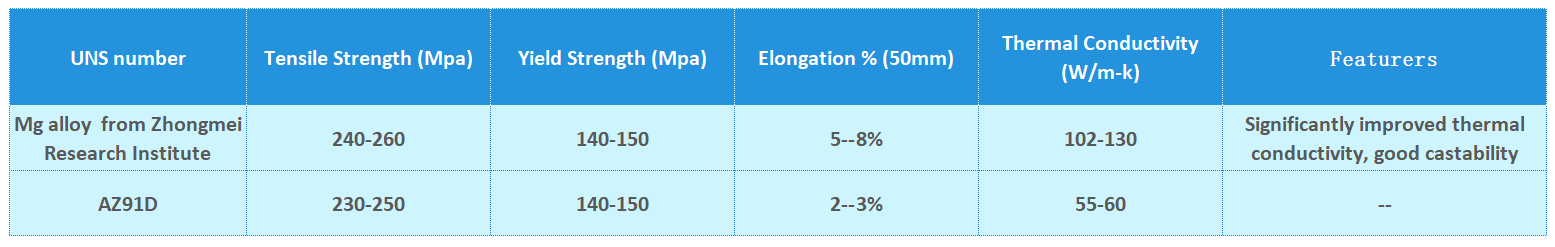

Mit dem Ziel, eine Mg-Legierung zu entwickeln, die im Vergleich zu den üblicherweise verwendeten AZ91D-Magnesiumlegierungen eine deutlich verbesserte Wärmeleitfähigkeit bieten kann, baute Zhongmei gemeinsam mit dem weltweit führenden Experten Prof. Pan Fusheng von der Chongqing University und seinem Team das Research Institute of Magnesium Alloy Materials auf.

Das Forschungsinstitut führt weiterhin Experimente und Tests durch und hat beachtliche Erfolge erzielt

Hauptvorteile

Verbesserte Wärmeleitfähigkeit von Magnesiumlegierungen – entscheidend in Anwendungen speziell zur Erhöhung der Wärmeaustauschkapazität und der Wärmesenke von technischen Komponenten.

Die verbesserte Wärmeleitfähigkeit kann die Arbeitstemperaturen von Endprodukten senken und somit die Energieeffizienz und Produktlebensdauer erhöhen.

Anwendungen

Elektrische Automobilindustrie

3C-Komponenten (Computer, Kommunikation und Verbraucherprodukt)

Komponenten von Kommunikationsbasisstationen und andere Kühlkörper

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com