In life, the use of mobile phones has been closely related to people’s lives, and people of all ages have their own mobile phones. The huge consumer market indicates a very large demand. Therefore, it is also a period of rapid development for the mobile phone manufacturing industry. While satisfying the functions of mobile phones, the processing of basic materials for mobile phones is also worthy of attention. Magnesium injection molding thixomolding mobile phone midplane is the soul accessory in mobile phone manufacturing, and this manufacturing process also requires very high technology.

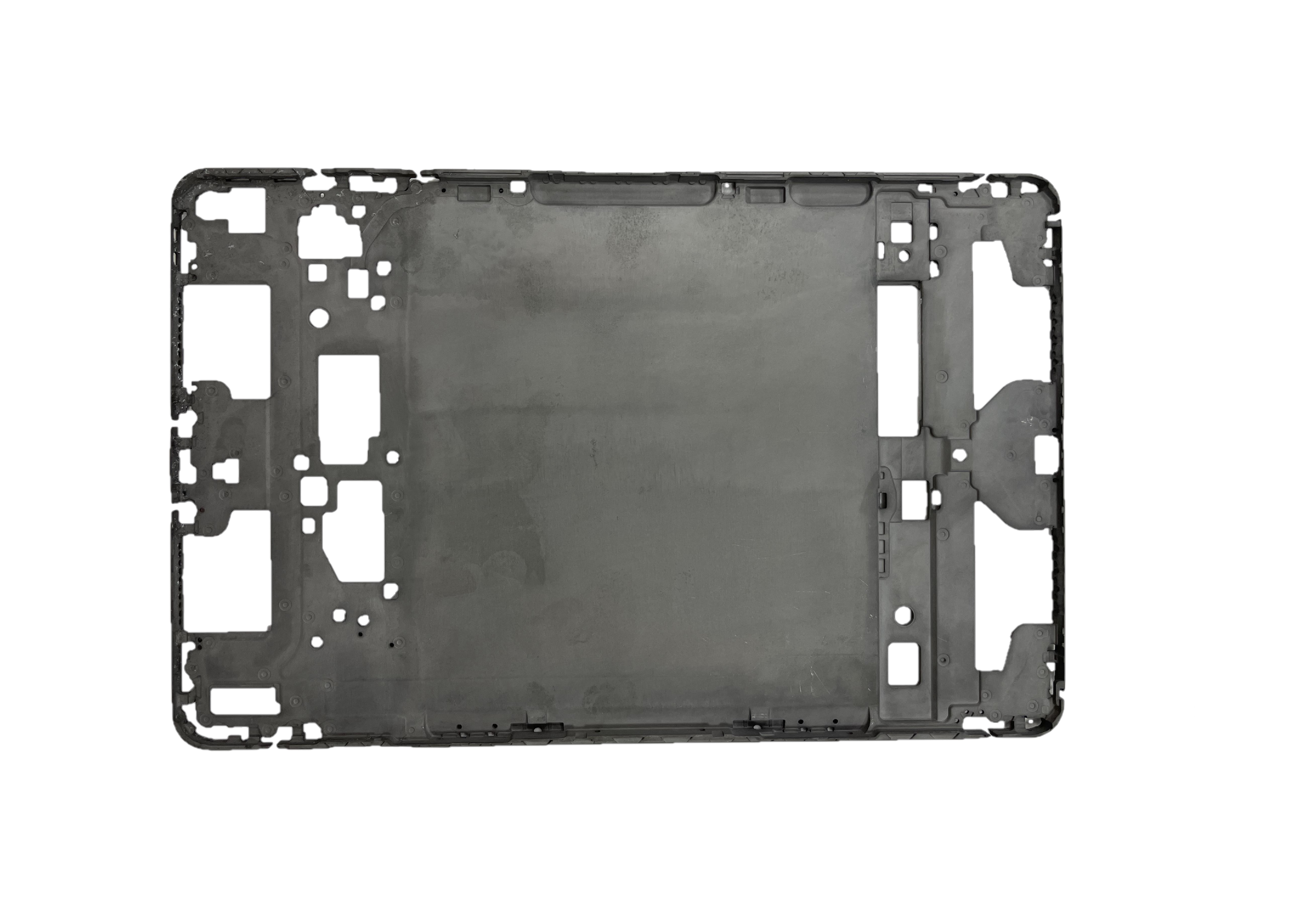

During the use of metal parts, magnesium has gradually become the basic material for metal parts due to its light weight, good elasticity and overall stability in die casting. In the process of forming metal parts, from the original liquid die-casting to the solid-state mode, it gradually develops into the solid-state molding mode. The process of injection processing is to inject raw materials directly into the mold through high-speed operation, so that the product can complete the entire molding process in one device. This manufacturing method greatly reduces the manufacturing process. Moreover, the use of magnesium alloys can be better adapted to this injection molding process.

Castable magnesium alloy is now mainly used in automobiles, electronic communications, notebook computers, medical equipment and other industries, and its light weight, low density, good metal fluidity, high electromagnetic interference barrier, good cutting performance, the entire material The dimensional accuracy is high. Therefore, the choice of magnesium injection molding in the manufacturing process of the mobile phone midplane can meet the requirements for production technology and the different requirements for material molding of different products.

When mobile phones have become an indispensable thing in our lives, magnesium alloy has also become an indispensable raw material in the middle plate of magnesium injection-molded thixotropic mobile phones. In the production process, it can better complete refined operations and provide products Bring better use effect.

-

- Kundenspezifische Gießereiprodukte E-Bike-Komponenten Magnesiumlegierungsrad

-

- Hochpräzises Druckguss-Lenkrad für die Automobilindustrie

-

- Laptopgehäuseabdeckung C

-

- Fahrradteile und Komponenten aus Magnesiumlegierung für Laufräder für Kinder

-

- OEM-Druckguss-Service-Metallkomponenten von MacBook Mitte

-

- Hochpräzise Druckgussteile aus Magnesiumlegierung für Kfz-Zündschlösser

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com