Introduction:

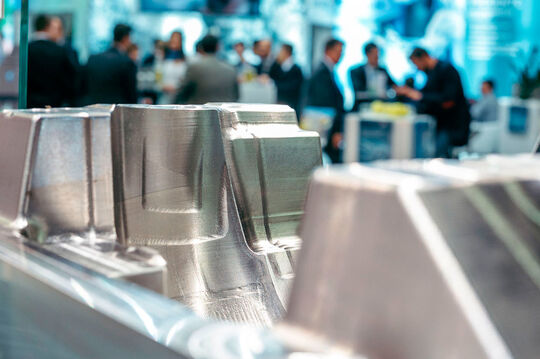

Aluminum machining is an important process in the aluminum industry. With its lightweight, high strength, and excellent corrosion resistance properties, aluminum has become a widely used material in various industries such as automotive, aerospace, and construction. To meet the increasing demand for precision engineered aluminum components, manufacturers must have a thorough understanding of the machining process and its challenges. This guide aims to provide a comprehensive overview of aluminum machining, including its benefits, techniques, and considerations.

Benefits of Aluminum Machining:

1. Lightweight: Aluminum is known for its low density, making it an ideal choice for applications where weight reduction is crucial. Machining aluminum allows manufacturers to create lightweight components without compromising on strength and durability.

2. High strength: Despite its lightweight nature, aluminum exhibits excellent strength properties. Through precise machining techniques, manufacturers can create complex and intricate aluminum parts that can withstand high stress and heavy loads.

3. Corrosion resistance: Aluminum naturally forms a protective oxide layer on its surface, providing excellent resistance against corrosion. This makes it a preferred material in industries exposed to harsh environments, such as marine and offshore applications.

Aluminum Machining Techniques:

1. CNC Machining: Computer Numerical Control (CNC) machining is widely used in aluminum machining due to its precision and efficiency. CNC machines can accurately follow programmed instructions to produce complex aluminum parts with tight tolerances.

2. Turning: Turning is a machining process where a cutting tool removes material from a rotating workpiece. This technique is commonly used to create cylindrical components like shafts, rods, and tubes. Turning is suitable for both small and large-scale aluminum machining.

3. Milling: Milling involves removing material from a workpiece using rotary cutters. It is a versatile technique that can produce a wide range of aluminum shapes, including slots, pockets, and complex geometries. Milling can be performed manually or using CNC machines.

Considerations for Aluminum Machining:

1. Chip control: Aluminum machining generates chips that can cause issues if not properly controlled. Special attention should be given to chip evacuation to prevent chip build-up and tool damage. Techniques like high-pressure coolant systems and proper tool selection can aid in effective chip control.

2. Tooling selection: Aluminum machining requires specific tooling designed to withstand the unique properties of the material. Carbide or high-speed steel tools with sharp cutting edges are commonly used for aluminum machining. Proper tool selection ensures efficient material removal and extends the tool’s lifespan.

3. Workholding: Securely holding the aluminum workpiece is crucial for accurate machining. Proper workholding techniques, such as using clamps, vises, or fixtures, ensure stability and prevent workpiece movement during machining operations.

Conclusion:

Aluminum machining plays a vital role in the aluminum industry, enabling manufacturers to produce precision engineered components. The lightweight, high strength, and corrosion resistance properties of aluminum make it a preferred material in various industries. Understanding the benefits, techniques, and considerations of aluminum machining is essential for achieving high-quality results. By utilizing CNC machining, turning, milling, and considering chip control, tooling selection, and workholding techniques, manufacturers can optimize their aluminum machining processes and meet the demands of their customers.

-

- Στήριγμα αυτόματου ταμπλό μηχανικής κατεργασίας CNC

-

- Πλαίσιο οθόνης LED από κράμα μαγνησίου

-

- Thixomolding parts & components mobile phone middle board processed

-

- Πλαίσιο από κράμα μαγνησίου υψηλής πίεσης OEM για ποδήλατο

-

- Integrated 3-spoke wheel for MTB with CNC machining &surface treatment

-

- Περίβλημα ελεγκτή ανταλλακτικών αυτοκινήτων με χύτευση από κράμα μαγνησίου

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com