If your project requires a lightweight die casting component with an excellent strength-to-weight ratio, magnesium die casting is the logical option. Die casts magnesium alloy AZ91D, a high-purity alloy which offers good corrosion resistance for your magnesium parts, as well as the following benefits:

- Longer tool life

- Easiest alloy to machine

- Good thermal and electrical conductivity

- Excellent for thin-wall, complex parts

- Excellent noise and vibration dampening properties

- Provides excellent EMI & RFI shielding

- Good finishing characteristics

- Light weight (75% lighter than steel, 33% lighter than aluminum) with high strength

- Magnesium parts scrap material is 100% recyclable

What is Magnesium?

Magnesium is a base material for numerous alloys. AZ91D is the most common magnesium alloy for die casting. It offers excellent castability and toughness, and is an ideal material for light weight, highly durable parts.

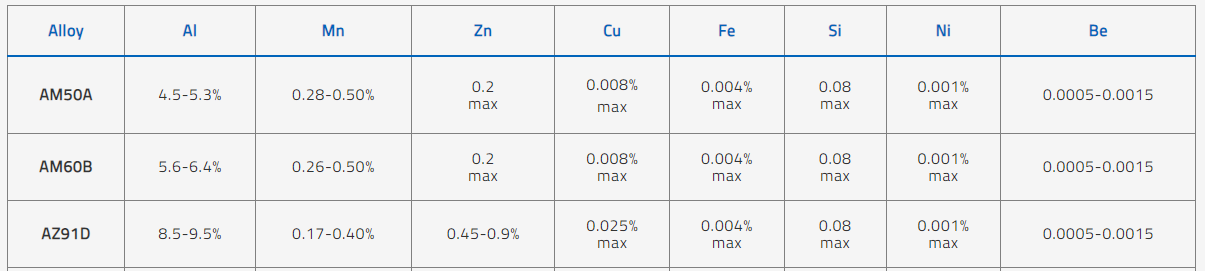

The alloy specification of three major magnesium alloys AM50A, AM60B, and AZ91D.

Why Choose Magnesium for your Die Casting Project?

Compared to steel, magnesium is 75% lighter with no significant loss of strength. It is a far better material for complex, thin-walled, net shape or near-net shape castings and offers greater dimensional stability. Magnesium castings can meet tight tolerances that would be difficult or impossible to achieve with steel. Tooling costs can be lower for magnesium castings, as multiple parts can be easily consolidated into a single component. This also improves component rigidity and reduces welding and assembly costs.

Compared to aluminum, magnesium is 33% lighter, with similar or improved mechanical properties, and machines easier. Magnesium provides greater corrosion resistance, and is better suited to large, thin-wall, net shape complex parts.

| Magnesium Die Casting | Primary Benefit of Mg | Secondary Benefit of Mg |

| vs. Steel Weldment | 75% Lighter | Less Expensive |

| vs. Aluminium Die Casting | 33% Lighter | Longer Tool Life |

| vs. Plastic Molding | Stronger, stiffer | Environmentally Stable |

Magnesium is stronger and stiffer than even the most advanced engineered plastics. It also provides greater wear resistance, higher temperature resistance, and better energy absorption/impact resistance characteristics.

The application of Magnesium

The applications for magnesium are wide ranging. Below are some areas we commonly see magnesium metal used in, for more information, please visit the International Magnesium Association (IMA) website.

AUTOMOTIVE APPLICATION:

In the 1920s magnesium began to make an appearance in the automotive industry. The lightweight metal was initially used in racing cars to add to their competitive edge. About a decade later, magnesium was widely used in commercial vehicles such as the Volkswagen Beetle, which contained about 20kg (44.09lbs) of the material. The interest in magnesium use for automotive applications has increased over the past ten years in response to increasing environmental and legislative influences. Nowadays, fuel efficiency, increased performance, and sustainability are top-of-mind issues for automotive producers.

The use of magnesium in vehicles can, and does, lower overall weight and improve each of these conditions. Many large automotive companies have already replaced steel and aluminum with magnesium in various parts of their products. Audi, DaimlerChrysler (Mercedes-Benz), Ford, Jaguar, Fiat and Kia Motors Corporation are just a few of these companies. Magnesium is currently being used in gearbox, steering column and driver’s air bag housings as well as in steering wheels, seat frames and fuel tank covers. The majority of magnesium parts are produced through high pressure diecasting.

To see an interactive demonstrator of where magnesium can be found in cars, visit the International Magnesium Associations website.

ALUMINUM APPLICATION:

One of the alloys that aluminum is alloyed with the most is magnesium. Magnesium offers a range of positive effects. This element can increase the strength and hardness of aluminum while also increasing castability. Manufacturers also turn to magnesium when they need to strengthen aluminum without making the alloy significantly denser. Magnesium and aluminum can also experience an increase of weldability as well as corrosion resistance.

The addition of magnesium to 5xxx series aluminum increases strength through solid solution strengthening and improves their strain hardening ability. These alloys are the highest strength nonheat-treatable aluminum alloys and are, therefore, used extensively for structural applications. The 5xxx series alloys are produced mainly as sheet and plate.

The addition of magnesium and silicon to 6xxx series aluminum produces the compound magnesium-silicide (Mg2Si). The formation of this compound provides the 6xxx series their heat-treatability. The 6xxx series alloys are easily and economically extruded and common applications for the 6xxx series alloys are handrails, drive shafts, automotive frame sections, bicycle frames, tubular lawn furniture, scaffolding, stiffeners and braces used on trucks, boats and many other structural fabrications.

AEROSPACE APPLICATION:

The aerospace industry has a long history of using magnesium in many applications both civil and military. Magnesium is critical to lowering the weight of air and space craft, as well as to aid in decreasing emissions and increasing fuel efficiency. Magnesium is an ideal material for use in these applications due to limited improvements on aluminum weight reduction, the high cost of fibre metal laminates or carbon fibre composites, and the poor impact, and damage properties of low-density plastics when subjected to extreme temperatures. Magnesium can be found in the thrust reversers for the Boeing 737, 747, 757, and 767 as well as in jet engine fan frames, and aircraft and helicopter transmission casings. Recent changes to the Aircraft Seat Design Standard SAE AS8049C now permit the use of magnesium alloys, meeting specific FAA flammability criteria, in passenger aircraft seat frames. Investigations are underway to allow broader use within the cabin. Due to increasing adoption, the aerospace industry is widely seen as the next growth segment for the magnesium market.

-

- 2022 Χονδρική Hot Sale Ανταλλακτικά ποδηλάτων από κράμα μαγνησίου Παιδικό ποδήλατο χωρίς ισορροπία πεντάλ Παιδικά Πολλαπλά χρώματα Διαθέσιμα

-

- Ποδήλατα για παιδιά Παιδικά Ποδήλατα για Παιδιά 3-16 ετών /OEM Baby Children Cycle Kids Mountain Bicycles 2022

-

- Magnesium alloy Thixomolding power batter housing

-

- Ηλεκτρικό ποδήλατο από κράμα μαγνησίου 12 ιντσών Ενσωματωμένος τροχός 36v10ah Ηλεκτρικό μοτοποδήλατο

-

- Thixomolding parts & components cell phone middle board processed

-

- Εξαιρετικά ελαφρύ πιρούνι ανάρτησης για MTB

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com