Integrated 3-spoke wheel for MTB with CNC machining &surface treatment

Cuadro de bicicleta de montaña de magnesio

Magnesium alloy bike parts & componenets for kid’s push bike

Customized foundry products high precision die-casting parts for e-bike integrated frame

OEM high pressure die casting magnesium alloy wheel for e-bike

Carcasa de motor de montaje medio de vehículo eléctrico de fundición a presión de aleación de magnesio

Customized foundry products e-bike components magnesium alloy wheel

Rueda de fundición a presión de aleación de magnesio para ebike

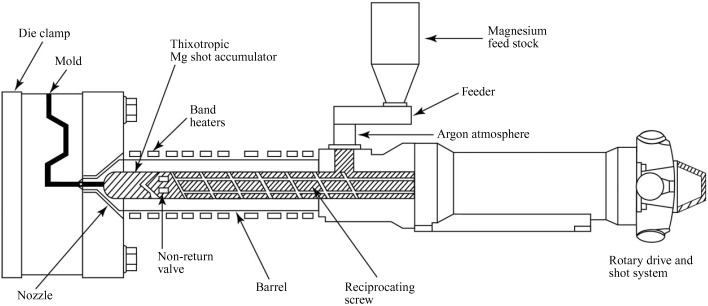

Fundición a presión de aleación de magnesio Piezas metálicas de tixomoldeo

Casco de fundición a presión de aleación de magnesio Thixomolding

Carcasa de masa de potencia de tixomoldeo de aleación de magnesio

Piezas y componentes de fundición a presión de aleación de magnesio para bicicletas eléctricas

Fundición a presión de aleación de magnesio Piezas metálicas de tixomoldeo

Carcasa de masa de potencia de tixomoldeo de aleación de magnesio

Piezas de tixomoldeo de aleación de magnesio para carcasa de máquina de succión de oxígeno

Soportes metálicos de tixomoldeo de fundición a presión de aleación de magnesio

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com