Räätälöidyt valimotuotteet sähköpyörän komponentit magnesiummetallivanteet

OEM korkeapaineinen painevalettu magnesiummetallivanne sähköpyörään

OEM korkeapainepainevalu magnesiumseoksesta valmistettu runko polkupyörälle

Magnesiumseosvalimoosien polkupyörän rungon CNC-työstö ja pintakäsittely

Integroitu 3-puolainen MTB-pyörä CNC-työstyksellä ja pintakäsittelyllä

Magnesiumseoksesta painevaluosat ja komponentit sähköpyörään

Customized foundry products high precision die-casting parts for e-bike integrated frame

Magnesiumseoksesta valmistettu painevalupyörä ebike-pyörälle

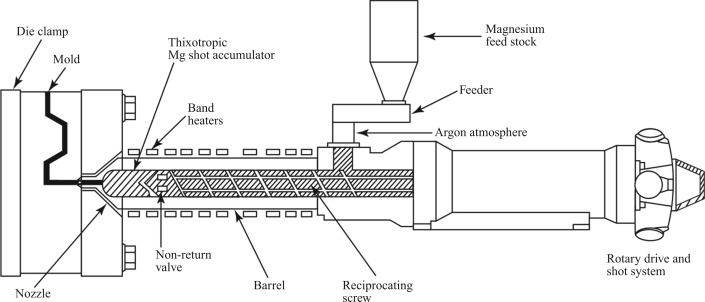

Magnesium alloy Thixomolding power batter housing

Magnesiumseoksesta painevaluosat ja komponentit sähköpyörään

Magnesium alloy Thixomolding power batter housing

Mangensiumseoksesta painevalu Thixomolding metalliosat

Magnesium alloy Thixomolding parts for oxygen suction machine housing

Mangensium alloy die-casting Thixomolding helmet

Mangensiumseoksesta painevalu Thixomolding metalliosat

Mangensiumseoksesta painevaluvat Thixomolding-metallijarrut

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com