Räätälöidyt valimotuotteet sähköpyörän komponentit magnesiummetallivanteet

Magnesiumseoksesta painevalettu sähköajoneuvon moottorikotelo

OEM korkeapaineinen painevalettu magnesiummetallivanne sähköpyörään

Magnesium alloy die-casting rigid fork for bike

Magnesiumseoksesta valmistettu painevalupyörä ebike-pyörälle

Magnesiumseoksesta painevaluosat ja komponentit sähköpyörään

Magnesiumseosvalimoosien polkupyörän rungon CNC-työstö ja pintakäsittely

Magensium mountain bike frame

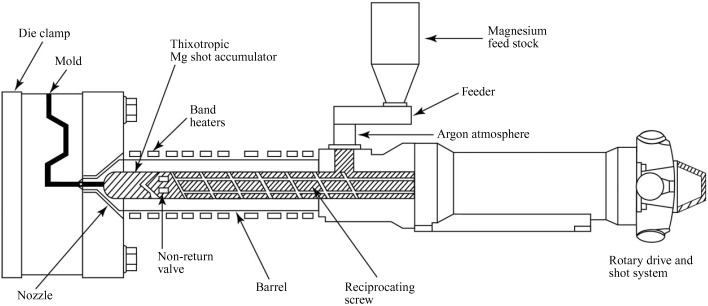

Magnesium alloy Thixomolding power batter housing

Mangensiumseoksesta painevaluvat Thixomolding-metallijarrut

Magnesium alloy Thixomolding parts for oxygen suction machine housing

Mangensium alloy die-casting Thixomolding helmet

Mangensiumseoksesta painevalu Thixomolding metalliosat

Magnesiumseoksesta painevaluosat ja komponentit sähköpyörään

Magnesium alloy Thixomolding power batter housing

Mangensiumseoksesta painevalu Thixomolding metalliosat

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com