We are a supplier of die castings, specializing in magnesium alloy materials. As a die casting supplier, I would like to share with you the difference between magnesium alloy and aluminum alloy.

According to the casting process of molten metal, casting can be divided into two types: gravity casting and pressure casting. Gravity casting is the process of injecting molten metal into a mold under the gravity of the earth, also known as casting. In a broad sense, gravity casting includes sand casting, metal casting, investment casting, foam lost foam casting, and mud casting. In a narrow sense, gravity casting refers to metal casting. Die casting refers to the process of injecting molten metal into the mold under the action of other external forces.

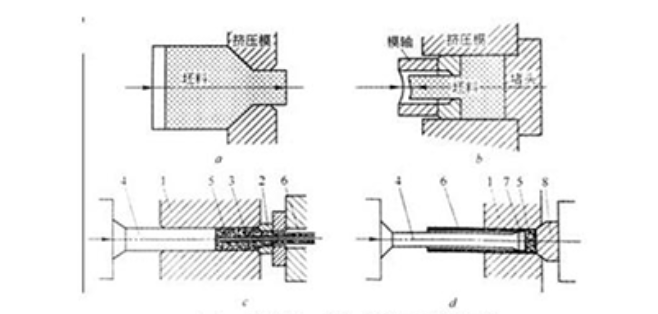

Die casting in a broad sense includes die casting and vacuum casting, low pressure casting, centrifugal casting, etc. Die-casting in a narrow sense refers to die-casting of die-casting machines, also known as die-casting. Precision casting manufacturers have long been engaged in gravity casting of sand molds and metal molds. These casting processes are currently common processes in non-ferrous metal casting. Die casting machines can be divided into hot chamber die casting and cold chamber die casting machines. Compared with the cold chamber die casting machine, the hot chamber die casting machine has a higher degree of automation, less material loss and high productivity.

However, due to the heat resistance of mechanical parts, it can only be used to produce castings of low melting point materials, such as magnesium alloys.

Due to its high melting point, aluminum alloy die castings widely used today can only be produced on cold die casting machines. The characteristic is that the metal liquid fills the cavity under high pressure and high speed, and forms and solidifies under high pressure.

Die castings also have disadvantages, because the metal liquid fills the cavity under high pressure and high speed. However, it is inevitable that the air in the cavity is wrapped in the casting to form subcutaneous holes, so aluminum alloy die castings should not be heat treated.

Otherwise, the internal holes in the casting will expand when heated, which can then cause the casting to deform or cause bubbles. In addition, the machining allowance of die castings should also be made small, generally about 0.5mm, which can reduce the weight of the castings, reduce the amount of cutting to reduce costs, and avoid infiltration into the dense surface layer, exposing subcutaneous pores, cause the workpiece to be scrapped.

The above is the difference between magnesium alloy castings and die castings. We are Taishan Zhongmei Technology Co., Ltd. If you want to know more about magnesium alloy products, please Contattaci or pay attention to our official website: http://www.zhongmei-tech.com.

-

- Parti in magnesio thixomolding coperchio dell'alloggiamento del laptop B

-

- Coperchio dell'alloggiamento del laptop con parti in magnesio pressofuso D

-

- Parti e componenti Thixomolding scheda centrale del telefono cellulare elaborata

-

- Prodotti di fonderia personalizzati parti pressofuse di alta precisione per telaio integrato e-bike

-

- Cornice per display a LED in pressofusione di lega di magnesio

-

- Parti e componenti pressofusi personalizzati

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com