In competing with aluminium alloys as structural materials, magnesium alloys have the advantages of low density, high strength ratio, better electromagnetic shielding properties and castability. These result in the preferential use of magnesium alloys in 3C components(Computer, Communication and Consumer product) where lightweight , heat dissipation, electromagnetic shielding is critical. also have extremely broad applications in the fields of automotive, aerospace,outdoor sports and so on.

With the high integration in 3C , removing the excessive heat produced during the operation of electronic components and heat exchangers, which causes the components to fail as a result of overheating or deformation, becomes more urgent. The demand for materials with both excellent heat dissipation and mechanical properties is increasing rapidly. Selecting materials with appropriate thermal conductivity is very important for achieving the best performance of components.

Mg合金は、Al合金よりも熱容量が小さく放熱効果が高いため、放熱材料として大きな可能性を秘めています。過去数十年にわたって、マイクロ、ナノ、さらには分子スケールでの基本的な熱伝達を明確に理解して、Mg 合金の熱伝導率を向上させることに専念してきたいくつかの努力がありました。

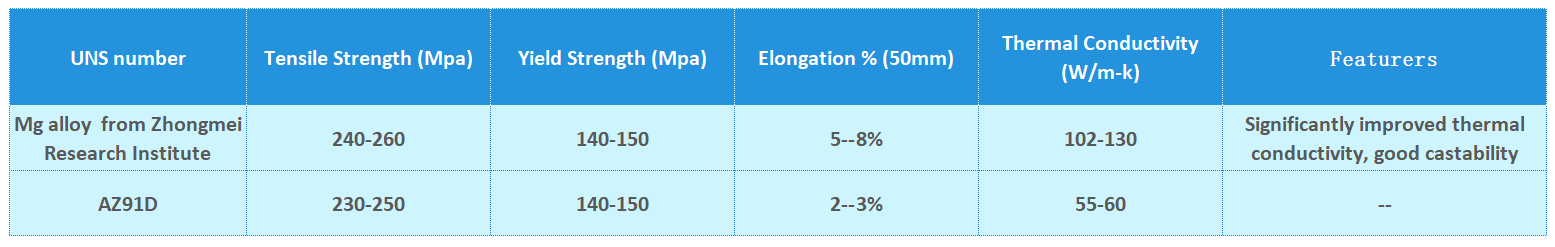

Aiming to develop a Mg alloys that can provide significantly improved thermal conductivity in comparison to the commonly used AZ91D magnesium alloys, Zhongmei built Research Institute of Magnesium Alloy Materials jointly with the global leading expert, Prof. Pan Fusheng of Chongqing University and his team.

研究所は実験とテストを続け、かなりの成果を上げています

主な利点

Improved thermal conductivity of magnesium alloys – critical in applications specifically for increasing the capacity of heat exchange and heat sink of engineering components.

熱伝導率の向上により、最終製品の動作温度が低下し、エネルギー効率と製品寿命が向上します。

アプリケーション

電気自動車産業

3C components(Computer, Communication and Consumer product)

通信基地局部品などのヒートシンク

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com