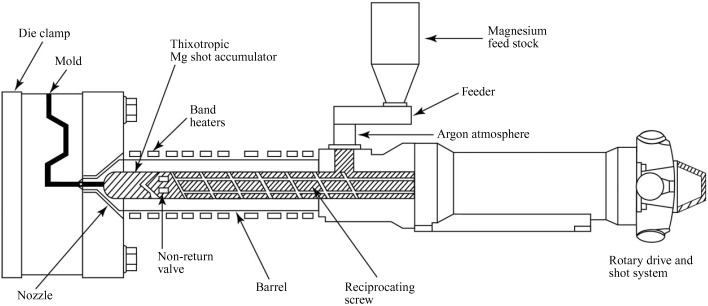

Magnesium alloy die casting is a manufacturing process that has been used for years to produce high-quality and cost-effective parts. This process involves injecting molten magnesium alloy into a die cavity, where it solidifies to create the desired shape. In this blog post, we’ll discuss the benefits and advantages of using magnesium alloy die casting.

Lightweight and Strong

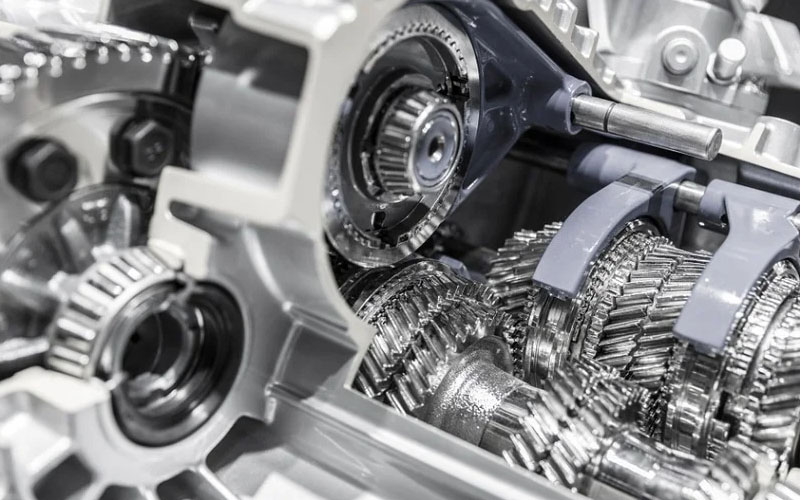

Magnesium alloy die casting offers a lightweight and strong solution for parts manufacturing. Magnesium is one of the lightest structural materials available, making it an excellent choice for parts that require strength and durability without adding unnecessary weight. Magnesium alloys also offer excellent strength-to-weight ratios, making them ideal for applications where weight reduction is critical.

High Thermal Conductivity

Magnesium alloys have high thermal conductivity, which means they can dissipate heat quickly. This property makes magnesium alloy die casting ideal for applications where thermal management is important, such as in electronics, automotive, and aerospace industries.

Good Corrosion Resistance

Magnesium alloys have good corrosion resistance, making them ideal for applications in harsh environments. They are resistant to a wide range of chemicals and can withstand exposure to saltwater, making them a popular choice for marine applications.

Dimensional Accuracy and Consistency

Magnesium alloy die casting offers excellent dimensional accuracy and consistency. The die casting process allows for precise control over the shape and size of the final part, ensuring that it meets the required specifications. This level of accuracy and consistency makes magnesium alloy die casting ideal for applications where tight tolerances are critical.

Cost-Effective

Magnesium alloy die casting is a cost-effective process. The die casting process is highly automated, which means that it can produce large quantities of parts quickly and efficiently. This makes it an ideal solution for high-volume production runs, where the cost per part can be significantly reduced.

결론

Magnesium alloy die casting offers a wide range of benefits and advantages, including lightweight and strong properties, high thermal conductivity, good corrosion resistance, excellent dimensional accuracy and consistency, and cost-effectiveness. With these benefits, magnesium alloy die casting is an excellent choice for a variety of applications, including electronics, automotive, aerospace, and marine industries.

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com