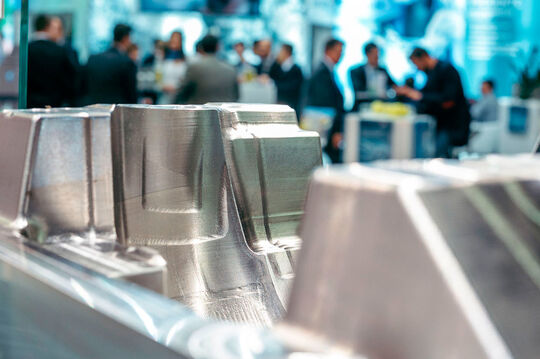

Aluminum alloy die casting is a manufacturing process used to produce high-quality metal parts. This process involves injecting molten aluminum alloy into a mold under high pressure. Once the aluminum solidifies, the mold is opened, and the finished part is removed. This process is used to produce parts with complex shapes and precise dimensions.

Aluminum alloy die casting is widely used in various industries, including automotive, aerospace, electronics, and consumer goods. This process offers several advantages over other manufacturing methods, such as high production efficiency, excellent dimensional accuracy, and reduced material waste.

One of the main advantages of aluminum alloy die casting is its high production efficiency. This process can produce a large number of parts in a short amount of time, which makes it ideal for mass production. Additionally, because the aluminum alloy is melted and injected into the mold under high pressure, the parts produced have excellent surface finish and dimensional accuracy.

Another advantage of aluminum alloy die casting is its ability to produce parts with complex shapes and thin walls. This process can produce parts with intricate details that may be difficult or impossible to achieve using other manufacturing methods. Additionally, the thin walls produced by this process reduce the weight of the finished part, which is important in industries such as automotive and aerospace.

Aluminum alloy die casting is also an environmentally friendly manufacturing process. Because this process produces parts with excellent dimensional accuracy, there is very little material waste. Additionally, the aluminum alloy used in this process is recyclable, which reduces the environmental impact of production.

Overall, aluminum alloy die casting is a versatile and efficient manufacturing process that offers several advantages over other methods. Its ability to produce parts with complex shapes, thin walls, and excellent dimensional accuracy makes it an ideal choice for many industries. Additionally, its efficiency and environmental friendliness make it a cost-effective and sustainable manufacturing process.

-

- Magnesium alloy die-casting auto parts center control cover

-

- Toge vilice iz magnezijeve zlitine za kovinske dele iz tlačnega litja kolesa

-

- Prenosno ohišje avtomobilskih delov iz tlačne litine iz magnezijeve zlitine

-

- UAV deli za tlačno vlivanje iz magnezijeve zlitine C

-

- UAV deli za tlačno vlivanje iz magnezijeve zlitine

-

- Pokrov ohišja prenosnega računalnika A z visoko natančnimi magnezijevimi tiksomlitnimi komponentami

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com