OEM high pressure die casting magnesium alloy wheel for e-bike

Magnesium alloy die-casting rigid fork for bike

Magnesium alloy bike parts & componenets for kid’s push bike

Customized foundry products e-bike components magnesium alloy wheel

โลหะผสมแมกนีเซียมหล่อชิ้นส่วนเฟรมจักรยานเครื่องจักรกลซีเอ็นซีและการตกแต่งพื้นผิว

Magnesium alloy rigid fork for bicycle -customized die casting metal parts

OEM high pressure die casting magnesium alloy frame for bicycle

Customized foundry products high precision die-casting parts for e-bike integrated frame

Magnesium alloy Thixomolding parts for oxygen suction machine housing

ชิ้นส่วนและส่วนประกอบหล่อโลหะผสมแมกนีเซียมสำหรับ e-bike

หมวก Thixomolding หล่อโลหะผสมแมงเกนเซียม

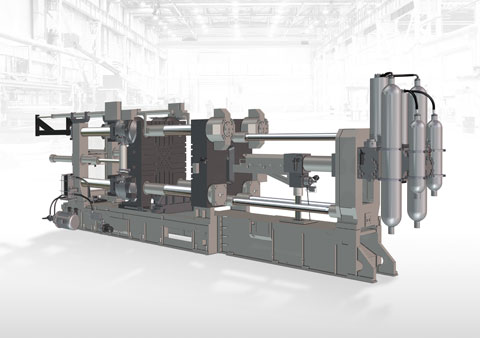

Mangensium alloy die-casting Thixomolding metal parts

Mangensium alloy die-casting Thixomolding metal parts

Magnesium alloy Thixomolding power batter housing

Magnesium alloy Thixomolding power batter housing

Mangensium alloy die-casting Thixomolding metal brakets

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com