Introduction

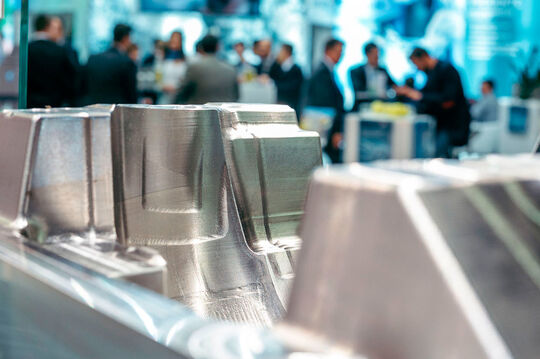

Aluminum die casting is a widely used manufacturing process in various industries due to its versatility, cost-effectiveness, and ability to produce complex parts with high precision. The quality of the die casting molds plays a crucial role in achieving efficient and reliable production. This article explores the key factors involved in creating high-quality aluminum die casting molds that contribute to efficient manufacturing processes.

Design Considerations for Die Casting Molds

Before the manufacturing of a die casting mold begins, careful consideration must be given to its design. The design of the mold should be optimized to ensure efficient production and minimize defects. Some key design considerations include:

1. Part geometry: The geometry of the part being produced determines the complexity and shape of the mold. Designing the mold to match the part geometry accurately is essential for achieving high-quality castings.

2. Draft angles: Incorporating appropriate draft angles into the mold design allows for easy ejection of the casting. This prevents any damage or deformation to the part during the mold opening process.

3. Cooling system: Proper cooling is crucial to ensure uniform solidification and minimize cycle time. Designing an efficient cooling system that evenly distributes cooling channels throughout the mold helps reduce casting defects and increase productivity.

Material Selection for Mold Making

The choice of material for mold manufacturing significantly impacts the quality and longevity of the mold. Some common materials used for aluminum die casting molds include:

1. H13 tool steel: This steel is widely used due to its excellent thermal conductivity, high hardness, and good resistance to wear and heat. H13 tool steel molds have a longer lifespan and can withstand high-temperature casting processes.

2. Aluminum alloys: For low-volume production or prototypes, molds made from aluminum alloys are a cost-effective option. Although they have a shorter lifespan compared to steel molds, aluminum molds are lighter, easier to machine, and offer faster cooling.

Surface Finish and Texture

The surface finish of the die casting mold greatly influences the final appearance and quality of the casted part. The mold surface should be smooth and free from defects to ensure high-quality castings. Some common surface finishes and textures used in die casting molds include:

1. High polish: A high polish finish provides a smooth and shiny surface on the casted part. It is ideal for parts that require a high aesthetic appeal or have tight tolerances.

2. Textured finish: Certain parts may require a specific texture, such as a matte or grainy surface. Adding texture to the mold surface can be achieved through various methods like etching or sandblasting.

Mold Maintenance and Repair

Regular maintenance of the die casting molds is essential to maximize their lifespan and ensure efficient production. Mold maintenance involves proper cleaning, lubrication, and inspection. Additionally, any damages or wear should be promptly repaired to prevent defects in the casted parts.

Conclusion

Creating high-quality aluminum die casting molds is crucial for achieving efficient and reliable production. By considering design factors, selecting appropriate materials, and maintaining the molds properly, manufacturers can optimize the manufacturing process and minimize defects. Investing in high-quality molds not only improves production efficiency but also enhances the overall quality of the casted parts.

-

- Custom-made metal parts macbook middle board produced

-

- میگنیشیم الائے ڈائی کاسٹنگ آٹو پارٹس ہیڈلائٹ فریم

-

- ہول سیل میگنیشیم الائے بیبی سائیکل 3 سے 5 سال کی عمر کے لیے 12 انچ بچوں کی سائیکل OEM سستی

-

- Magnesium alloy die-casting LED display frame

-

- سائیکل کے لیے میگنیشیم الائے سخت کانٹا - اپنی مرضی کے مطابق ڈائی کاسٹنگ میٹل پارٹس

-

- CNC مشینی حصے اسٹیئرنگ بریکٹ

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com