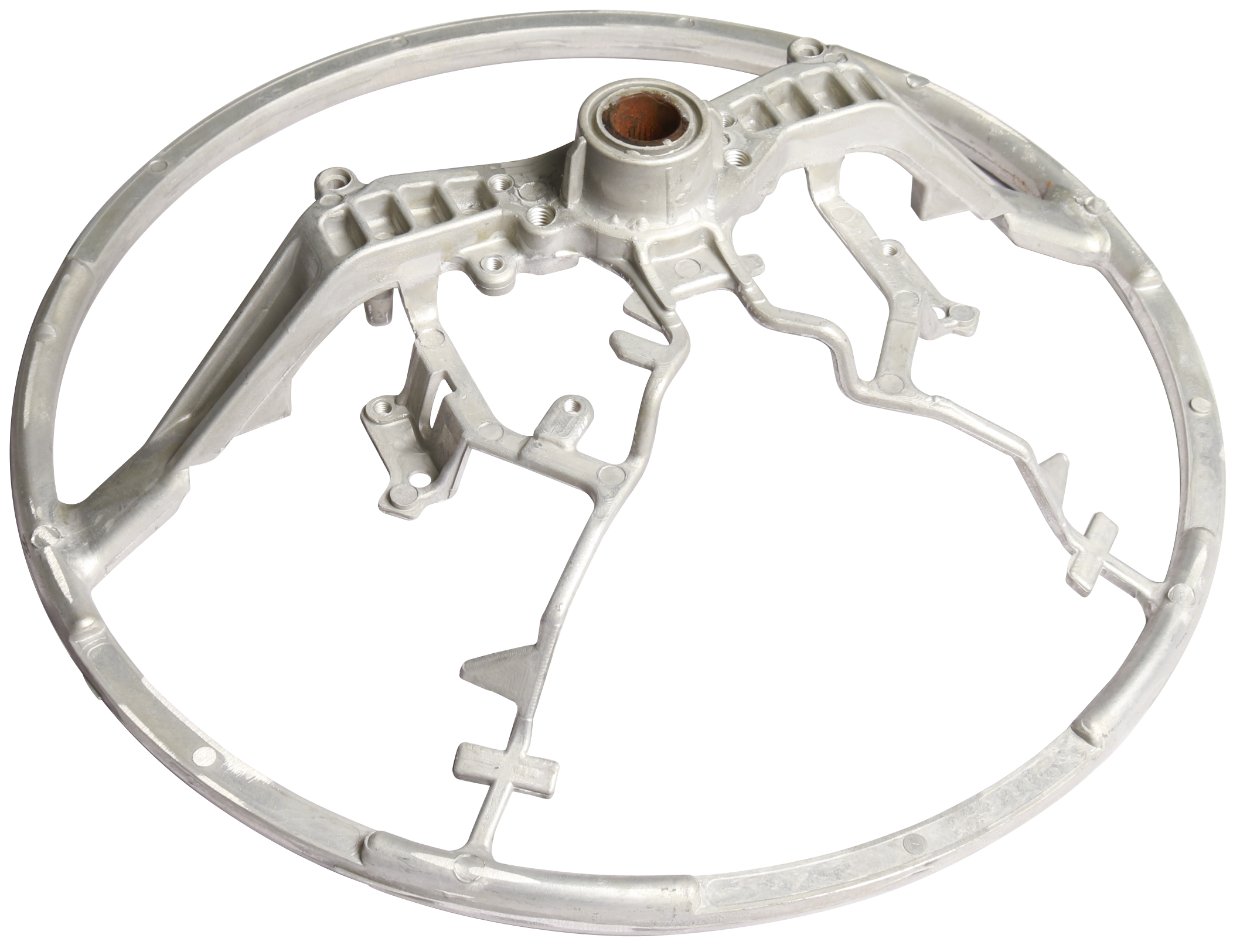

Die casting is a metal casting process whose main function is to inject molten metal liquid into the mold, and then use the pressure of the mold to shape the metal. The Customized foundry products high precision die-casting steering wheel for automotive also uses this technical condition to inject the metal liquid for manufacturing the steering wheel into the mold to form the steering wheel in one piece.

OEM products mean that the product is processed by a third party during the production process, and the client provides the processing party with the samples after the product is formed, as well as the raw materials that need to be used in the production process, and will Limit the parameters of the entire product. The main advantages of completing the assembly line manufacturing of related products within the specified parameter range are fast speed, high precision, and the ability to complete the production of the product within the specified time range.

At the same time, the use of molds can accurately control the accuracy of the product, and ensure that the product meets the requirements during the process of OEM completion. Most of the liquid metal used to make the steering wheel is magnesium alloy, because the density of magnesium alloy is small, and the weight of the product can be guaranteed to be lighter in the case of the same volume. Moreover, it has good elasticity, can withstand a certain impact load, and is more durable than aluminum alloy products. Therefore, whether it is the automobile manufacturing industry, the aviation industry or other industries, the utilization rate of magnesium alloys is constantly increasing.

And this one-piece product has a big advantage in that there are fewer welding points. In the previous process, the more welding points, the more problems will occur in the later stage. These welded parts are the main reasons for the failure. The high-precision die-casting automobile steering wheel of this customized OEM product successfully solved the welding problem by using advanced technology, and also increased the service life of the product, thereby creating more high-quality products in the automobile manufacturing industry.

-

- Magnesium Aluminium alloy die casting parts Chain cover for automotive

-

- Popular Children’s Sports Bicycle High Quality Children’s Balance Bike Children’s Bicycle

-

- Die cast magnesium parts laptop housing cover D

-

- Magnesium foundry parts Steering column

-

- موٹر سائیکل کے لیے میگنیشیم الائے ڈائی کاسٹنگ سخت فورک

-

- بچوں کے لیے سائیکلیں 3-16 سال کی عمر کے بچوں کے لیے سائیکلیں

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com