Aluminum die casting molds play a vital role in the manufacturing industry, enabling the production of complex and durable aluminum parts. This guide aims to provide insights into the process of creating an aluminum die casting mold, focusing on efficiency and precision. By following these guidelines, manufacturers can optimize their mold-making process, resulting in high-quality products and improved productivity.

Understanding the Die Casting Process

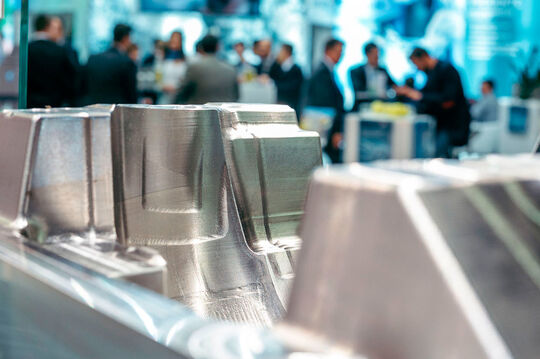

Before delving into the mold-making process, it is crucial to understand the fundamentals of aluminum die casting. Die casting is a manufacturing technique where molten metal, in this case, aluminum, is injected into molds under high pressure. Once the metal solidifies, the mold is opened, revealing the finished product. This process allows for the production of intricate and accurate parts with excellent surface finishes.

Designing the Mold

The first step in creating an aluminum die casting mold is designing it. A well-designed mold ensures optimal product quality and reduces manufacturing costs. Key factors to consider during the design process include:

1. Part geometry: Understand the shape, size, and complexity of the desired part. It is essential to design the mold to accommodate undercuts, draft angles, and appropriate wall thicknesses.

2. Gate and runner system: The gate and runner system is crucial for the flow of molten aluminum into the mold. Design it to minimize turbulence and ensure consistent filling.

3. Cooling system: Efficient cooling is essential to maintain uniform solidification and prevent defects. Design cooling channels within the mold to facilitate heat extraction.

4. Ejector system: The ejector system helps remove the solidified part from the mold. It is important to design a robust ejector system to ensure part integrity during ejection.

Choosing the Mold Material

Selecting the right mold material is crucial for the success of the die casting process. The mold material must possess high thermal conductivity, excellent dimensional stability, and resistance to thermal fatigue. Common mold materials for aluminum die casting include:

1. H13 tool steel: Known for its high hardness and excellent thermal resistance, H13 is a popular choice for mold manufacturing.

2. ADC12 aluminum alloy: ADC12 is a versatile aluminum alloy that offers good thermal conductivity and dimensional stability.

Manufacturing the Mold

Once the design and material selection are finalized, it\’s time to manufacture the mold. The mold-making process typically involves the following steps:

1. Machining: Start by machining the mold base and core inserts using computer numerical control (CNC) machines. CNC machining ensures high precision and repeatability.

2. Electrode production: Create electrodes for the mold using electrical discharge machining (EDM). EDM allows for intricate details and fine finishes.

3. Assembly: Assemble the mold components, including the mold base, inserts, and cooling system. Pay attention to proper alignment to avoid any issues during casting.

4. Surface finishing: Polish and texture the mold surfaces to achieve the desired surface finish on the final part. This step enhances the aesthetics and functionality of the end product.

Conclusion

Creating an aluminum die casting mold requires careful consideration of various factors, including design, material selection, and manufacturing techniques. By following the guidelines outlined in this guide, manufacturers can optimize their mold-making process, resulting in efficient and precise production. Investing time and effort into designing and manufacturing high-quality molds will ultimately lead to superior aluminum parts and increased overall productivity in the manufacturing industry.

-

- Magnesiumseoksesta painevalettu autonosien keskiohjauskansi

-

- Magnesium alloy die casting auto parts transfer case

-

- Integroitu 3-puolainen MTB-pyörä CNC-työstyksellä ja pintakäsittelyllä

-

- CNC machined parts Steering bracket

-

- 2022 Wholesale Hot Sale Bicycle Parts Magnesium Alloy Children Bike No Pedal Balance Bicycle Kids Multiple Colors Available

-

- Magnesiumseoksesta valmistettu tukkupyörä 3–5-vuotiaille 12 tuuman lasten pyörä OEM halvalla

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com