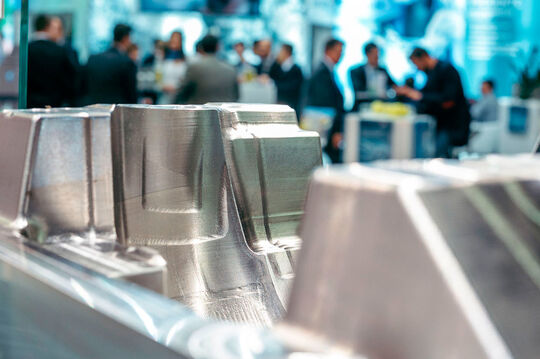

Die casting is a widely used manufacturing process that allows for the production of high-quality and complex metal parts. It involves injecting molten metal into a mold, which is then cooled and solidified to form the desired shape. This versatile manufacturing technique offers numerous advantages in terms of cost-effectiveness, efficiency, and durability.

At our company, we specialize in providing a diverse range of high-quality die casting products. With years of experience and expertise in the industry, we have established ourselves as a trusted supplier of precision-engineered components across various sectors.

One of the key advantages of die casting is its ability to produce parts with excellent dimensional precision. The molds used in the process are designed to accurately replicate the desired shape, resulting in parts that fit together seamlessly and function flawlessly. This level of precision is particularly crucial in industries such as automotive and aerospace, where even the smallest deviations can have significant consequences.

In addition to dimensional accuracy, die casting also allows for the creation of complex and intricate designs. The molten metal is forced into every nook and cranny of the mold, ensuring that even the most intricate details are faithfully reproduced. This makes die casting an ideal choice for producing parts with intricate geometries, such as turbine blades, engine components, and decorative features.

Furthermore, die casting offers excellent material properties. The solidification process during casting results in a fine-grained and dense structure, which translates into enhanced mechanical properties. This makes die cast parts highly durable and resistant to wear and tear. Additionally, the use of alloys allows for the incorporation of specific properties, such as high strength, heat resistance, and corrosion resistance, making die cast parts suitable for a wide range of applications.

Our company prides itself on delivering high-quality die casting products that meet the most stringent standards. We work closely with our customers to understand their specific requirements and provide tailored solutions. Our team of skilled engineers and technicians ensure that every step of the manufacturing process, from mold design to final finishing, is carried out with precision and attention to detail.

To meet the diverse needs of our customers, we offer a wide selection of materials for die casting, including aluminum, zinc, magnesium, and copper-based alloys. Each material has its own unique set of properties and advantages, allowing us to produce parts that are customized to meet specific performance requirements.

In addition to the production of die cast parts, we also offer secondary operations such as machining, surface treatment, and assembly. This comprehensive range of services allows us to provide our customers with finished products that are ready for immediate use, saving them time and resources.

We take pride in our commitment to quality and continuous improvement. Our manufacturing facilities are equipped with advanced technology and state-of-the-art machinery, ensuring that every product that leaves our premises is of the highest standard. We adhere to strict quality control measures throughout the production process, conducting rigorous inspections and tests to ensure that every part meets the required specifications.

Our company offers a diverse range of high-quality die casting products that are tailored to meet the specific needs of our customers. With our expertise and commitment to excellence, we have gained a reputation for delivering precision-engineered components that are durable, reliable, and cost-effective. Whether you require small or large volumes, simple or complex designs, we have the capabilities to meet your requirements. Partner with us for all your die casting needs, and experience the difference of high-quality manufacturing.

-

- Magnesium-alumiiniseoksesta valmistettu lasten pyörä 3-8 vuotta vanha halvalla kuumalla 14 tuuman lasten pyörä FOREVER tukkumyynti 2022

-

- Magnesium alloy die-casting LED display frame

-

- Magnesiumseoksesta painevaluosat ja komponentit sähköpyörään

-

- Erittäin tarkkoja magnesiumtiksomuovauskomponentteja kannettavan tietokoneen kotelon kansi A

-

- Magnesiumseoksesta valmistettu jäykkä haarukka polkupyörän räätälöityihin painevalettavissa metalliosiin

-

- Bicycle Freehub 12/14/16 Inch Children Bike Low Rider Bikes Magnesium Aluminum Alloy Children Bicycle 3-8 Years Old In Stock

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com