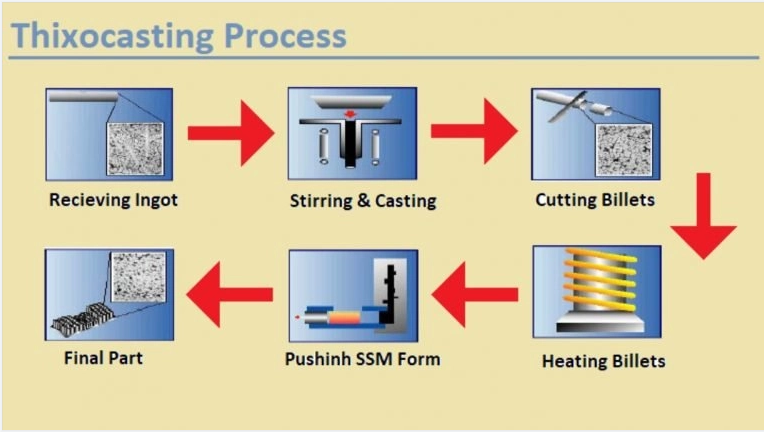

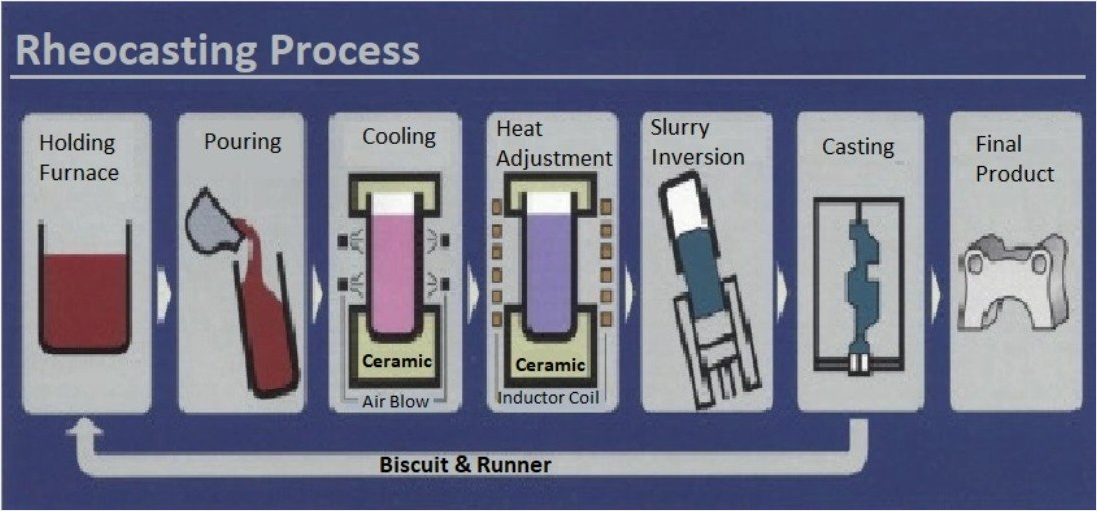

Introduction: Semi-solid metal (SSM) casting process is a recent casting technique which combines the advantage of liquid metal casting with the advantage of solid metal forging. This process is mainly used to cast complex products with near net shapes and excellent dimensional accuracy. Semi solid metal casting which is also known as thixocasting, rheocasting, thixoforming, or thixomolding, etc. is suitable to cast non-ferrous metals such as aluminum, copper, or magnesium.

Process: In semi solid metal casting, metal is melted at temperature where slurry remains at a temperature between the solid and liquid state. The ideal tempature is upto to 10�C at which the metal is in a slurry state which is 30% to 60% solid. The metal which is melted and cooled, during which dendrites that are formed are broken up. In this state the metal is further process into the desired castings. To maintain uniform structure and quality of the castings, care must be taken to to homogeneously distribute the solid metal without liquid is segregated.

Due to the lower pressures and temperatures that is required for semi-solid casting, expensive die cast metals are not required. Graphite or softer stainless steels and also non-ferrous dies can be used. The special structure of the semi-solid metal gives it some added advantage. Though the metal flows in a mushy shape, it retains the properties of the solid structure, thus ensuring a better control.

There are a number of different techniques to produce semi-solid castings. The special structure of semi-solid structure gives it special advantage. For aluminum alloys the more common processes are thixocasting and rheocasting. Other process such as strain induced melt activation (SIMA) and RAP can also be used with aluminum alloys, although are less common commercially. With magnesium alloys, the most common process is thixomolding.

Dendrites: A dendrite the tree-like structural growth of the crystal formed as the molten metal freezes. The dendrite growth has a great influence on the material properties of metals like its ductility. The morphology of the dendrites is altered using mechanical, electromagnetic or other forces. The dendrites can be viewed ina metal by polishing the casting.

Application: Semi-solid processing is ideally suited for the production of large volume die casting components, including light weight, high strength components for automobiles. For aluminum alloys typical parts include engine suspension mounts, air manifold sensor harness, engine blocks and oil pump filter housing. For magnesium alloys, semi-solid casting is typically used to produce extremely thin walled castings, such as computer and camera bodies. Because of this the process can be applied to rapid prototyping needs and mass production.

The Advantages of Semi Solid Metal Casting:

- Complex parts produced in near net shapes

- Excellent mechanical performance

- Thin walls can be caste can be done

- Casting are heat treatable

- No air entrapment during the casting process

- Low shrinkage during solidification

- Uniform microstructure of the entire cast.

For further information about our semi-solid metal casting services, contact us via the convenient website form or submit a request for quote directly.

-

- OEM-painevalukomponentit autojen istuimen runkoon

-

- Mangensiumseoksesta painevaluvat Thixomolding-metallijarrut

-

- Sähköpyörän magnesiumseoksesta valmistettu 12 tuuman integroitu pyörä 36v10ah sähkömopo

-

- Magnesiumseoksesta painevaluosat ja komponentit sähköpyörään

-

- Magnesiumseoksesta painevalettu sähköajoneuvon moottorikotelo

-

- Räätälöidyt valimotuotteet sähköpyörän komponentit magnesiummetallivanteet

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com