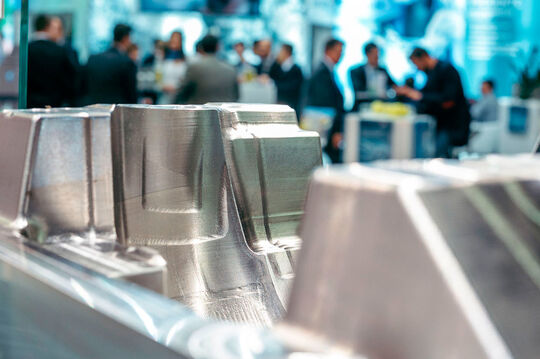

The production of high-quality aluminum die-cast products relies heavily on the flawless design and manufacturing of molds. A flawlessly designed mold ensures the production of precise and defect-free products. This comprehensive guide will delve into the various aspects involved in creating flawless aluminum die-cast molds.

Mold Material Selection:

Selecting the right material for the mold is crucial for achieving flawless results. Aluminum alloys such as H13, P20, and 8407 are commonly used due to their excellent thermal conductivity, high hardness, and resistance to wear. These materials ensure durability and efficient heat transfer during the casting process.

Mold Design:

A well-designed mold is the backbone of flawless aluminum die casting. Attention should be given to factors such as gating system design, mold cavity layout, and ejector pin placement. Proper consideration of these aspects ensures uniform filling, minimal turbulence, and efficient ejection of the cast part.

Gating System Design:

The gating system plays a vital role in controlling the flow of molten aluminum into the mold cavity. It consists of the sprue, runner, and gates. The design should focus on achieving a balanced flow with minimal turbulence to prevent defects like entrapped air and cold shuts. Simulations and computer-aided design tools can be utilized to optimize the gating system.

Mold Cooling:

Efficient cooling is essential for maintaining consistent mold temperatures and reducing cycle times. Proper cooling channels should be designed to ensure uniform heat dissipation throughout the mold. This prevents uneven solidification, shrinkage, and warpage in the cast part. The use of water-based cooling systems can enhance cooling efficiency.

Surface Finish:

A flawless mold surface finish is crucial for achieving smooth and defect-free casting surfaces. The mold surfaces should be carefully machined and polished to the desired level of smoothness. High-quality finishes, such as diamond polishing, can be applied to minimize surface defects like porosity and blemishes on the cast part.

Mold Maintenance:

Regular mold maintenance is necessary for sustained flawless mold performance. Cleaning, lubrication, and inspection should be carried out to prevent mold degradation and prolong its lifespan. Wear and tear parts, such as ejector pins and sliders, should be replaced to avoid potential defects in casting.

Quality Control:

Implementing stringent quality control measures ensures the flawless manufacturing of aluminum die cast molds. In-process inspections, dimensional checks, and defect analysis should be performed at various stages of the mold manufacturing process. This ensures adherence to specifications and identifies any potential issues early on.

Continuous Improvement:

Constantly striving for improvement is key to creating flawless molds. Feedback from production and inspection should be analyzed to identify areas for enhancement. Process optimization, material selection, and design modifications should be considered to achieve higher mold performance and produce superior cast parts.

Conclusion:

Creating flawless aluminum die cast molds requires meticulous attention to detail in material selection, design, cooling, and maintenance. The implementation of quality control measures and continuous improvement efforts is essential for achieving consistent and defect-free casting results. By following this comprehensive guide, manufacturers can enhance mold performance and ultimately produce high-quality aluminum die cast products.

-

- Magnesium alloy die-casting rigid fork for bike

-

- Magnesíumblendi steypuhlutar reiðhjólagrind CNC vinnsla og yfirborðsfrágangur

-

- OEM Die casting manufacturer produce magnesium alloy wheel for kids push bike

-

- Mangsíum álfelgur deyja-steypu Thixomolding málm bremsur

-

- Hlíf fyrir fartölvuhús C

-

- Magnesium alloy die-casting Auto parts Front bumper Anti-collision beam

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com