What is foundry manufacturing?

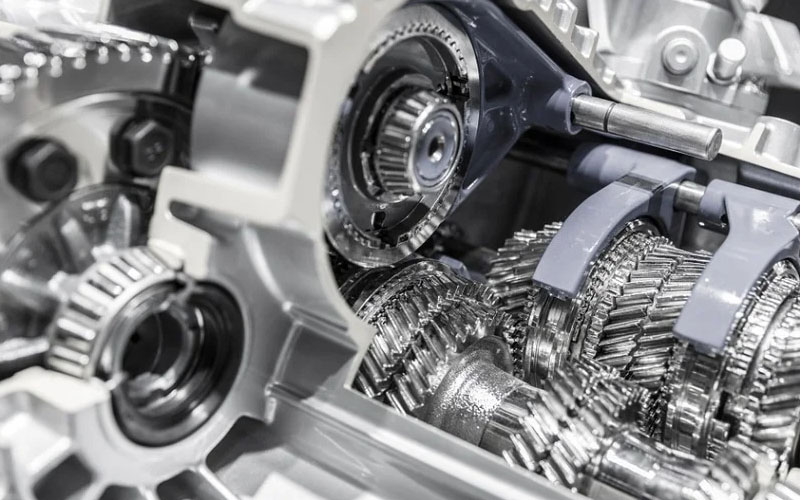

Manufacturing foundry products begins with the production of a sand mold. This mold is made by packing sand around a pattern that is the shape of the desired product. The sand is then vibrated to remove any air pockets and to help the mold hold its shape. The pattern is then removed, and the mold is ready to be used in the foundry.

The molten metal is poured into the mold and allowed to cool. After the metal has cooled, the sand is removed to reveal the finished product. Casting is a very versatile process and can be used to produce a wide variety of products.

2. The benefits of foundry manufacturing

There are many benefits of foundry manufacturing. Perhaps the most important benefit is that foundry manufacturing allows companies to produce high-quality parts and products quickly and efficiently. Additionally, foundry manufacturing is a cost-effective way to produce parts and products in large quantities. Finally, foundry manufacturing is a reliable way to produce parts and products that meet customer specifications.

-

- Magnesium Aluminum Alloy Children Bike 3-8 Years Old Cheap Hot Sale 14 Inch Children Bicycle FOREVER Wholesale 2022

-

- Mangsíum álfelgur deyja-steypu Thixomolding málm bremsur

-

- Hlíf fyrir fartölvuhús C

-

- OEM Die casting manufacturer produce magnesium alloy wheel for kids push bike

-

- Heildsölu magnesíumblendi barnahjól fyrir 3 til 5 ára 12 tommu krakkahjól OEM Ódýrt

-

- Sérsniðin verksmiðja Kína Bmx Cycles Road Sport Kids Reiðhjól 12 16 18 20 tommur Cycle Mtb fyrir krakka 6-10 ára

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com