The first one-time molding Magnesium alloy eBike Frame made by 3000T die-casting machine

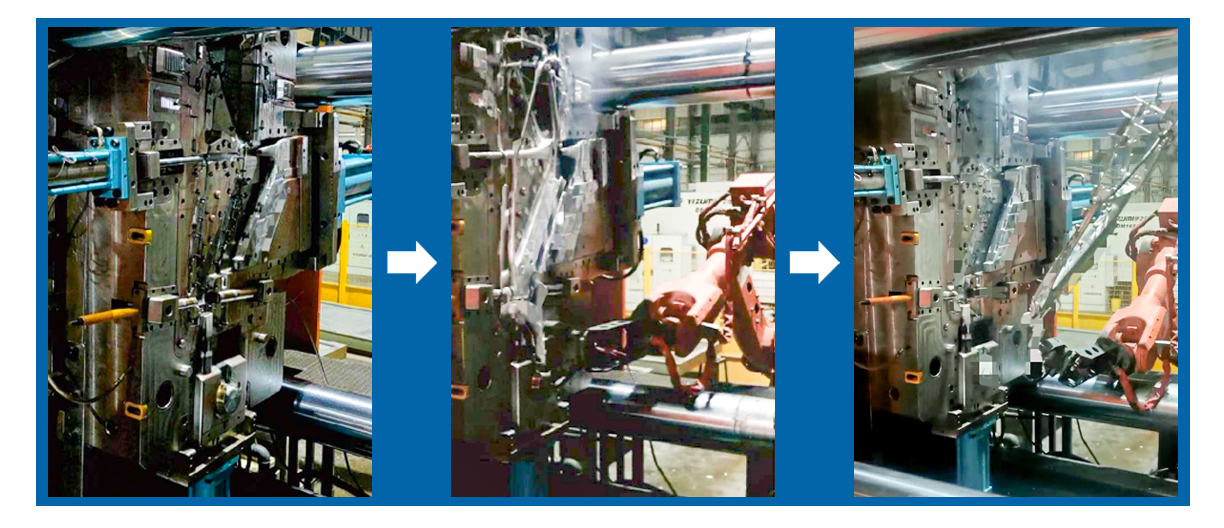

Zhongmei Technology developed its first 27.5” integrated magnesium alloy eBike frame, This is a one-time molding frame without any welding joints, installed with a BAFANG central motor, made by a die-casting machine with 3000 ton lock force once for all. With the combination of magnesium alloy materials and fluid molding technology in injection molding, Zhongmei Technology is now capable of producing lightweight, stiff frames with hollow-tube geometry. The frames are 100% recyclable and have a 50% reduction in carbon emissions during manufacture compared with the current state-of-the-art technology. 30% lighter than traditional aluminum alloy frames.

General Manager Japson Feng: “we have finally brought landmark change on the mass production of bicycle frames. With our first one-time molding magnesium alloy eBike frame in large size, Zhongmei Technolgoy proves that efficient mass production of light-weight, large size integrated bike frames with very high stiffness in China is possible. Zhongmei Technology can produce 600 frames a day per mold; with a single manipulator arm, a complete frame is produced in just below 120 seconds, one-time molding without any welding lines. With high production volumes, it saved the production cost, improved the effieciency, minimize the defects dramastically while reducing the CO2 emissions by more than 50%. At the same time, the frames offer higher stiffness, ligher weight and better ridding experience than aluminium frames. This is a revolution in production technology for bicycle frames. Our plant is capable of producing up to 2 million bike frames per year. We are looking forward to seeing the extraordinary impact this will have on the industry!”

Complete test-bikes are also available.

Zhongmei Technology provides turnkey solutions for OEMs, including frame development, frame simulation, mold design, mold manufacturing, process optimisation and mass production in China. Zhongmei Technology focuses on lightweight integrated frame, folding frame, wheels for bike/eBike/scooter .

Please email to sales@zhongmei-tech.com for more information.

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com