The magnesium alloy machine for injection molding is used for automobile and motorcycle parts because the workpiece produced by the magnesium alloy injection molding machine will have fewer pores. But the cost is high, because he needs to make magnesium alloy ingots into raw materials like plastic pellets, and then after baking, they can enter the screw and extrude into the mold cavity. At present, the most commonly used magnesium alloy hot-chamber machine is the hot-chamber machine, because the hot-chamber machine has a fast die-casting speed, and can directly put magnesium alloy ingots into the furnace. the workpiece, the cost is relatively low.

There are also manufacturers using cold room machines, but the cold room machines are not suitable for the appearance parts of mobile phones, because after the magnesium alloy soup is melted, it has to undergo air oxidation, and the mold clamping does not make the room machine large, so do Mobile phone in-app purchases can also be used. As for die casting and injection molding, the process is the same.

Production prices are low. The overall price is low. Lightweight. But bear the weight to be small. Breaks easily. Relatively short lifespan. There are a few post-processing steps.

Die casting is a manufacturing process that has become increasingly popular due to its efficiency and precision. The process involves melting metal and injecting it into a mold to create a specific shape. The mold is a critical component in the die casting process as it determines the final shape and quality of the product. In this article, we will discuss the steps involved in developing a high-quality die casting mold for efficient production. Step 1: Designing the Mold The first step in developing a high-quality die casting mold is designing the mold. The mold designer must consider various...

もっと見る >>

Aluminum alloy die casting is a manufacturing process that is widely used in the production of high-quality metal parts. It is a popular method for producing complex, intricate shapes with excellent dimensional accuracy, surface finish, and mechanical properties. This manufacturing process involves the use of high-pressure injection of molten metal into a die or mold. The aluminum alloy is melted in a furnace and then injected into the die at high pressure, where it solidifies and takes the shape of the mold. This article discusses the various aspects of aluminum alloy die casting and how it ensures high-quality manufacturing. ...

もっと見る >>

Introduction Die casting is a widely used manufacturing process for producing high-quality metal parts with complex shapes and tight tolerances. It involves injecting molten metal into a die cavity under high pressure, followed by rapid cooling to solidify the metal and produce the desired part. However, to achieve optimal results, careful design considerations are essential. This article presents guidelines for die casting design, focusing on optimizing the manufacturing process. Design Considerations 1. Material Selection The choice of material is crucial in die casting design. Aluminum, zinc, and magnesium alloys are commonly used due to their excellent...

もっと見る >>

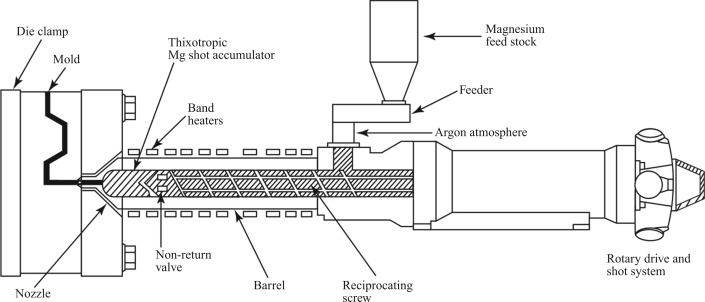

Introduction As industries across the world look for ways to reduce their carbon footprint and increase efficiency, lightweight materials have become increasingly popular for a wide range of applications. One such material is magnesium, a lightweight metal that offers several benefits over traditional materials like steel and aluminum. However, working with magnesium can be challenging due to its unique properties. Thankfully, a new process called magnesium thixomolding has emerged as an innovative solution for producing lightweight metal parts. Background Magnesium has been used in a variety of industries for many years, including aerospace, automotive, and electronics. Its...

もっと見る >>

Introduction In recent years, there have been significant advancements in medical CNC machining, which has revolutionized precision manufacturing in the healthcare industry. CNC, or Computer Numerical Control, machining refers to the automated control of machining tools through the use of computers. The integration of CNC technology in medical manufacturing has led to improved precision, efficiency, and quality in the production of medical devices and equipment. This article will explore the various advancements in medical CNC machining and their impact on the healthcare industry. Enhanced Precision and Accuracy One of the most significant advantages of medical CNC machining...

もっと見る >>

Aluminum alloy die casting is a popular manufacturing solution that offers a strong and lightweight finished product. This process involves melting aluminum alloy and injecting it into a mold under high pressure, resulting in the creation of complex and precise shapes. One of the key advantages of aluminum alloy die casting is the strength it offers. Aluminum is a durable and hard-wearing material that can withstand a great deal of stress and pressure. This makes it ideal for use in products that need to be strong and long-lasting, such as automotive parts, machinery components, and structural components. In...

もっと見る >>