What are thixotropic parts, and why are they desirable?

Thixotropic parts are those that are not easily deformable when at rest, but that become more deformable when put into motion. This is desirable in many parts, as it gives them a higher resistance to wear and tear. Additionally, it can help to keep them in place and prevent them from moving around too much.

What are some of the benefits of magnesium alloy thixotropic parts?

There are a number of benefits to using magnesium alloy thixotropic parts in manufacturing. Some of the key benefits include:

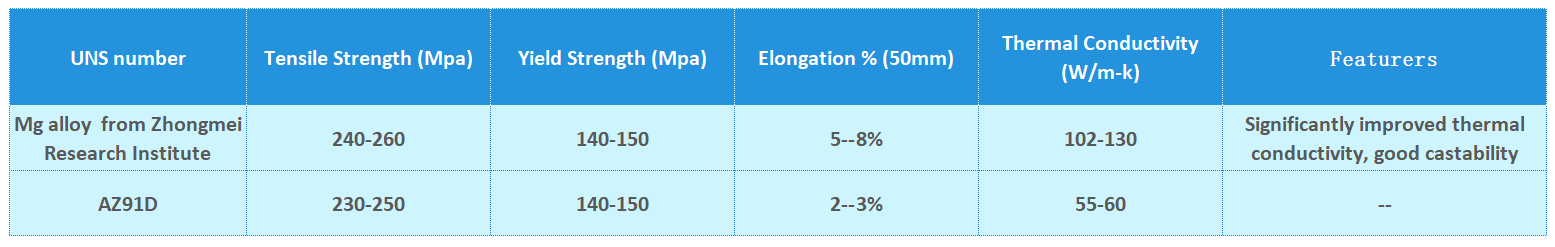

1. Increased Strength – Magnesium alloy thixotropic parts are stronger than traditional magnesium parts, making them more durable.

2. Improved Fatigue Resistance – Magnesium alloy thixotropic parts also have improved fatigue resistance, making them more resistant to damage over time.

3. Enhanced Corrosion Resistance – Magnesium alloy thixotropic parts also have enhanced corrosion resistance, making them more resistant to rust and other forms of degradation.

4. Better Machinability – Magnesium alloy thixotropic parts are also easier to machine than traditional magnesium parts, making them less expensive to produce.

What are some of the potential drawbacks of magnesium alloy thixotropic parts?

One potential drawback of using magnesium alloy thixotropic parts is that the material can be more brittle than traditional magnesium alloy parts. Additionally, magnesium alloy thixotropic parts can be more expensive to produce, and may not be as strong as traditional magnesium alloy parts.

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com