Precision CNC machining, also known as computer numerical control machining, is a cutting-edge technology that has revolutionized the manufacturing industry. With its ability to produce highly accurate and complex parts, it has taken manufacturing to the next level. In this article, we will explore the benefits and applications of precision CNC machining.

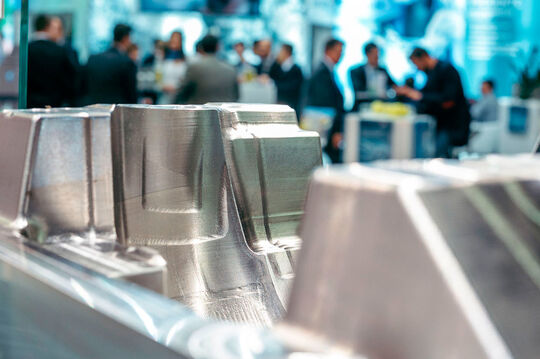

Precision CNC machining involves the use of computer-controlled machines to remove material from a workpiece to create a desired shape and size. The process starts with a CAD (computer-aided design) model, which is then converted into a program that controls the machine’s movements. The machine uses various tools such as drills, lathes, and mills to cut and shape the material according to the program’s instructions.

One of the key advantages of precision CNC machining is its ability to produce parts with a high degree of accuracy. The machines are capable of achieving tolerances as low as 0.001 inches, ensuring that each part meets the required specifications. This level of precision is crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can have severe consequences.

Another benefit of precision CNC machining is its ability to produce complex parts that would be difficult or impossible to create using traditional machining methods. The machines can perform multiple operations, such as milling, turning, and drilling, in a single setup, allowing for the creation of intricate shapes and features. This versatility not only saves time but also reduces the risk of errors that can occur when transferring the workpiece between different machines.

In addition to accuracy and complexity, precision CNC machining offers several other advantages. One of these is its efficiency. The machines can run continuously, 24 hours a day, 7 days a week, allowing for high-volume production with minimal downtime. This is especially beneficial for large-scale manufacturing operations that require a high output rate.

Furthermore, precision CNC machining can also improve the consistency and repeatability of parts. Once a program is created, it can be used to produce identical parts repeatedly, ensuring that each piece meets the same quality standards. This is particularly important in industries where interchangeability is crucial, such as in the production of automotive components.

The applications of precision CNC machining are vast and diverse. It is used in industries ranging from aerospace and automotive to electronics and healthcare. In the aerospace industry, precision CNC machining is used to create complex parts for aircraft engines, wings, and landing gear. In the automotive industry, it is used to manufacture engine components, transmission parts, and chassis components. In the electronics industry, precision CNC machining is used to produce circuit boards, connectors, and housings. In the healthcare industry, it is used to create orthopedic implants, surgical instruments, and prosthetics.

In conclusion, precision CNC machining has revolutionized the manufacturing industry by offering unparalleled accuracy, complexity, efficiency, and consistency. Its ability to produce highly accurate and complex parts has made it an indispensable technology in industries such as aerospace, automotive, electronics, and healthcare. As technology continues to advance, precision CNC machining will likely play an even greater role in shaping the future of manufacturing.

-

- Bicycle Freehub 12/14/16 Inch Children Bike Low Rider Bikes Magnesium Aluminum Alloy Children Bicycle 3-8 Years Old In Stock

-

- Bahagian&komponen die-casting aloi magnesium untuk e-basikal

-

- parts&comopnents for bicycle suspension fork for MTB

-

- Basikal Elektrik Aloi Magnesium 12 inci Roda Bersepadu 36v10ah Moped Elektrik

-

- Komponen thixomolding aloi magnesium

-

- Die-casting aloi magnesium Bahagian Auto Langkah sisi Papan larian

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com