Die casting is a widely used manufacturing process in which molten metal is forced into a mold cavity under high pressure. It is known for its ability to produce complex shapes with high accuracy and excellent surface finish. One crucial element in achieving flawless die casting products is the use of precision die casting molds.

Precision die casting molds are specially designed and manufactured to ensure the highest level of quality and precision in the final casted product. These molds are made from high-quality materials, such as steel or aluminum alloys, which can withstand the high temperatures and pressures involved in the die casting process.

The first step in creating flawless die casting products is the design and engineering of the precision die casting mold. This process involves the use of advanced software and techniques to create a 3D model of the desired product. The mold design takes into consideration factors such as the material being casted, the desired shape and dimensions, and the required tolerances.

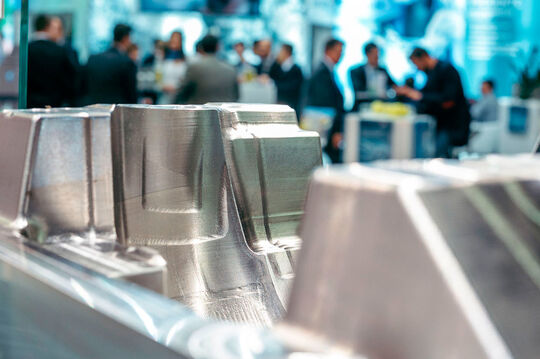

Once the mold design is finalized, the manufacturing of the precision die casting mold begins. This involves the use of precision machining techniques, such as milling, drilling, and grinding, to create the mold cavities and other necessary features. The mold is then heat-treated to increase its hardness and durability.

After the precision die casting mold is manufactured, it undergoes a rigorous testing and inspection process to ensure its quality and performance. This includes dimensional checks, surface finish analysis, and mold flow simulations to ensure proper filling of molten metal during the casting process.

When the precision die casting mold is ready for production, it is mounted onto a die casting machine. The machine injects molten metal, typically aluminum or zinc alloys, into the mold cavity at high pressures. The molten metal fills the mold cavities and takes the shape of the desired product.

The precision die casting mold plays a critical role in the quality and precision of the final die casting product. A well-designed and properly manufactured mold ensures that the molten metal flows evenly and fills the mold cavities with high accuracy. This results in products with consistent dimensions, excellent surface finish, and minimal defects.

The use of precision die casting molds also allows for the production of complex shapes and intricate details that would be difficult or impossible to achieve using other manufacturing processes. Die casting molds can be designed to incorporate features such as undercuts, thin walls, and fine surface textures, providing endless design possibilities for a wide range of industries, including automotive, aerospace, and consumer electronics.

Precision die casting molds can be designed for multiple cavities, allowing for the simultaneous production of multiple parts in a single cycle. This not only improves production efficiency but also reduces costs, making die casting an economically viable option for high-volume production.

Precision die casting molds are essential for creating flawless die casting products. These molds are designed and manufactured with high precision and quality to ensure the accurate filling of molten metal and the production of products with consistent dimensions and excellent surface finish. The use of precision die casting molds enables the production of complex shapes and intricate details, making it a preferred manufacturing process for a wide range of industries. With the right precision die casting mold, manufacturers can achieve superior quality and efficiency in their die casting operations.

-

- Magnesium alloy die-casting Auto parts RDM housing

-

- Die-casting aloi magnesium Bahagian Auto Langkah sisi Papan larian

-

- OEM die casting components for automotive Seat frame

-

- Mangensium alloy die-casting Thixomolding helmet

-

- Basikal Sukan Kanak-Kanak Berkualiti Tinggi Basikal Imbangan Kanak-kanak Basikal Kanak-Kanak

-

- Bahagian&komponen die-casting aloi magnesium untuk e-basikal

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com