Introduction:

Manufacturing processes have undergone tremendous transformations. One such revolutionary process is die casting, which has emerged as a cornerstone of the manufacturing industry. This article explores the mastery of die casting products and how they have revolutionized the manufacturing sector.

1. What is Die Casting?

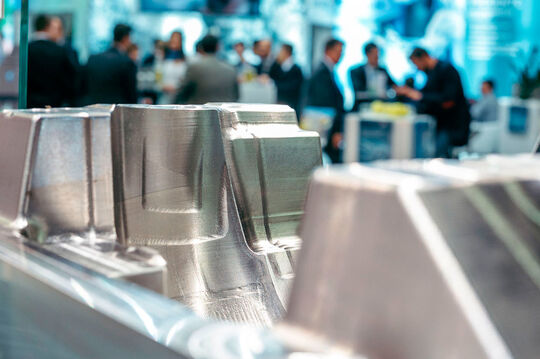

Die casting is a manufacturing process that involves the injection of molten metal into a mold, under high pressure. The molten metal is forced into intricate shapes and forms, resulting in highly precise and complex products. This process allows for the production of parts with excellent dimensional accuracy and surface finish, making it ideal for mass production.

2. Evolution of Die Casting:

Die casting has a rich history that dates back to the 1830s when the first patent for a die-casting machine was filed. Over the years, advancements in technology, materials, and equipment have propelled die casting to new heights. Today, die casting is widely used in various industries, including automotive, aerospace, electronics, and consumer goods.

3. Advantages of Die Casting:

Die casting offers numerous advantages that have contributed to its widespread adoption in manufacturing. These advantages include:

– Cost Efficiency: Die casting allows for high-volume production, resulting in lower costs per unit. The process minimizes material waste, making it economically viable for large-scale manufacturing.

– Design Flexibility: Die casting offers immense design freedom, allowing manufacturers to create products with intricate shapes and complex geometries. This flexibility enables the production of customized parts to meet specific requirements.

– Excellent Surface Finish: Die casting produces products with exceptional surface finish and dimensional accuracy, eliminating the need for extensive post-processing. The final products exhibit a smooth texture, enhancing their aesthetics and functionality.

– Superior Strength and Durability: Die casting products possess excellent strength-to-weight ratios, making them lightweight yet robust. This characteristic is particularly beneficial in industries such as aerospace and automotive, where weight reduction is critical.

4. Materials Used in Die Casting:

A wide range of materials can be used in die casting, including aluminum, zinc, magnesium, and copper-based alloys. Each material possesses unique properties that make it suitable for different applications. Aluminum, for example, is lightweight and corrosion-resistant, making it ideal for automotive and aerospace parts.

5. Die Casting Process:

The die casting process involves several steps, including mold preparation, metal melting, injection, solidification, and part ejection. High-quality molds and advanced equipment are essential for achieving precise and consistent results. Computer-aided design (CAD) and simulation tools have further enhanced the accuracy and efficiency of the die casting process.

6. Die Casting Applications:

Die casting finds applications in various industries due to its versatility and cost-effectiveness. Some common applications include:

– Automotive: Die casting is extensively used in the automotive industry for manufacturing engine components, transmission cases, and structural parts.

– Electronics: The high precision and dimensional accuracy of die casting make it suitable for producing electronic enclosures, connectors, and heat sinks.

– Aerospace: Die casting is employed in the aerospace industry to produce lightweight yet strong components, including turbine blades and structural parts.

– Consumer Goods: Die casting is used to manufacture a wide range of consumer goods, such as kitchen appliances, power tools, and decorative items.

Conclusion:

Die casting has revolutionized the manufacturing industry by offering a cost-effective and efficient method of producing complex and high-quality products. With continuous advancements in technology and materials, die casting is poised to continue its dominance in various industries. The mastery of die casting products has truly transformed the manufacturing landscape, enabling the production of innovative and reliable solutions.

-

- Magensium mountain bike frame

-

- 2022 Wholesale Hot Sale Bicycle Parts Magnesium Alloy Children Bike No Pedal Balance Bicycle Kids Multiple Colors Available

-

- OEM die casting service metal components of macbook middle

-

- OEM die-casted parts& components

-

- Литье под давлением из магниевого сплава Автозапчасти Корпус РДМ

-

- Литье под давлением сплава марганца Тиксоформование металлических деталей

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com