Introduction

In recent years, the use of magnesium casting has gained significant momentum in various industries. With its exceptional properties such as lightweight, high strength-to-weight ratio, and excellent corrosion resistance, magnesium casting has emerged as a preferred choice for manufacturing durable parts. This article explores the evolution of magnesium casting and its impact on the production of lightweight and durable components.

Historical Background

Magnesium is one of the most abundant elements on Earth, but its industrial usage began relatively late due to challenges in extraction and processing. The first successful commercial production of magnesium occurred in the early 20th century, and it quickly gained popularity in the aerospace industry due to its low density. However, its application was limited due to the difficult casting process and its tendency to catch fire.

Advancements in Casting Techniques

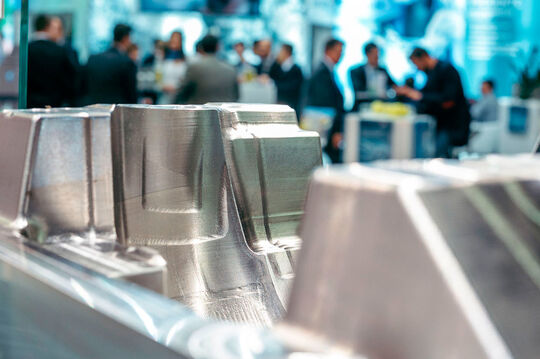

Over time, significant advancements have been made in the casting techniques for magnesium. The development of high-pressure die casting (HPDC) and gravity casting methods have revolutionized the production process, making it more efficient and cost-effective. HPDC involves injecting molten magnesium into a steel mold under high pressure, resulting in complex and intricate parts with excellent dimensional accuracy. Gravity casting, on the other hand, relies on the force of gravity to fill the mold, making it suitable for larger and bulkier components.

Benefits of Magnesium Casting

The evolution of magnesium casting has led to numerous benefits for various industries. One of the key advantages is its lightweight nature, as magnesium is 35% lighter than aluminum and 78% lighter than steel. This property makes it highly desirable in industries such as automotive, aerospace, and electronics, where weight reduction is crucial for improving fuel efficiency and performance. Additionally, magnesium\’s high strength-to-weight ratio allows for the production of parts that can withstand heavy loads while maintaining structural integrity.

Furthermore, magnesium casting offers excellent corrosion resistance, especially when compared to other metals like steel or cast iron. This property makes it ideal for applications in environments with high humidity or exposure to chemicals, such as marine or industrial settings. Moreover, magnesium\’s superior heat dissipation capabilities have made it a popular choice in electronic devices where thermal management is critical.

Applications of Magnesium Casting

The evolution of magnesium casting has paved the way for its extensive application across various industries. In the automotive sector, magnesium is used to produce engine blocks, transmission cases, and structural components, resulting in reduced vehicle weight and improved fuel efficiency. Furthermore, the aerospace industry utilizes magnesium casting for aircraft components, such as engine parts, landing gears, and structural elements, contributing to reduced fuel consumption and increased payload capacity.

In the electronics industry, magnesium casting finds its application in mobile devices, laptops, and tablets, where its lightweight and heat dissipation properties are highly valued. Additionally, the healthcare industry benefits from magnesium casting in the production of medical devices, prosthetics, and implants, as it offers biocompatibility and ease of customization.

Challenges and Future Outlook

Despite its numerous advantages, magnesium casting still faces certain challenges. One of the primary concerns is the higher cost compared to aluminum or steel. However, ongoing research and technological advancements are aimed at reducing the production cost and improving the overall competitiveness of magnesium casting.

The future outlook for magnesium casting appears promising. Continued development in alloy compositions and casting techniques will further enhance the mechanical properties and expand the potential applications of magnesium. Moreover, the increasing focus on sustainable manufacturing practices and the growing demand for lightweight materials will likely drive the adoption of magnesium casting in various industries.

Conclusion

Magnesium casting has evolved significantly over the years, transforming it into a preferred choice for manufacturing lightweight and durable parts. With its remarkable properties and advancements in casting techniques, magnesium casting has found widespread applications in automotive, aerospace, electronics, and healthcare industries. While challenges remain, ongoing research and technological developments are expected to further propel the growth of magnesium casting, making it a vital component in the manufacturing of future products.

-

- Po meri izdelani thixomolding deli UAV komponente s CNC obdelavo in površinsko obdelavo

-

- OEM proizvajalec tlačnega litja proizvaja avtomobilsko armaturno ploščo iz magnezijeve zlitine

-

- Okvir LED zaslona iz tlačne litine iz magnezijeve zlitine

-

- Vgrajeno 3-krako kolo za MTB s CNC obdelavo in površinsko obdelavo

-

- CNC obdelani deli Nosilec krmila

-

- Toge vilice iz magnezijeve zlitine za kovinske dele iz tlačnega litja kolesa

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com