When there was a computer at the beginning, everyone would be curious about this relatively large product, but would also be overwhelmed by its advanced technology and the information it brought. However, with the continuous development of technology, everyone’s requirements for the use of laptops have also changed. Higher and higher. It is hoped that the weight of the entire computer will become lighter and lighter when the screen is required to be large enough, which is also a big test for the raw materials of the computer shell. The high-precision magnesium thixomolding notebook computer case makes lightness the ideal weight for everyone.

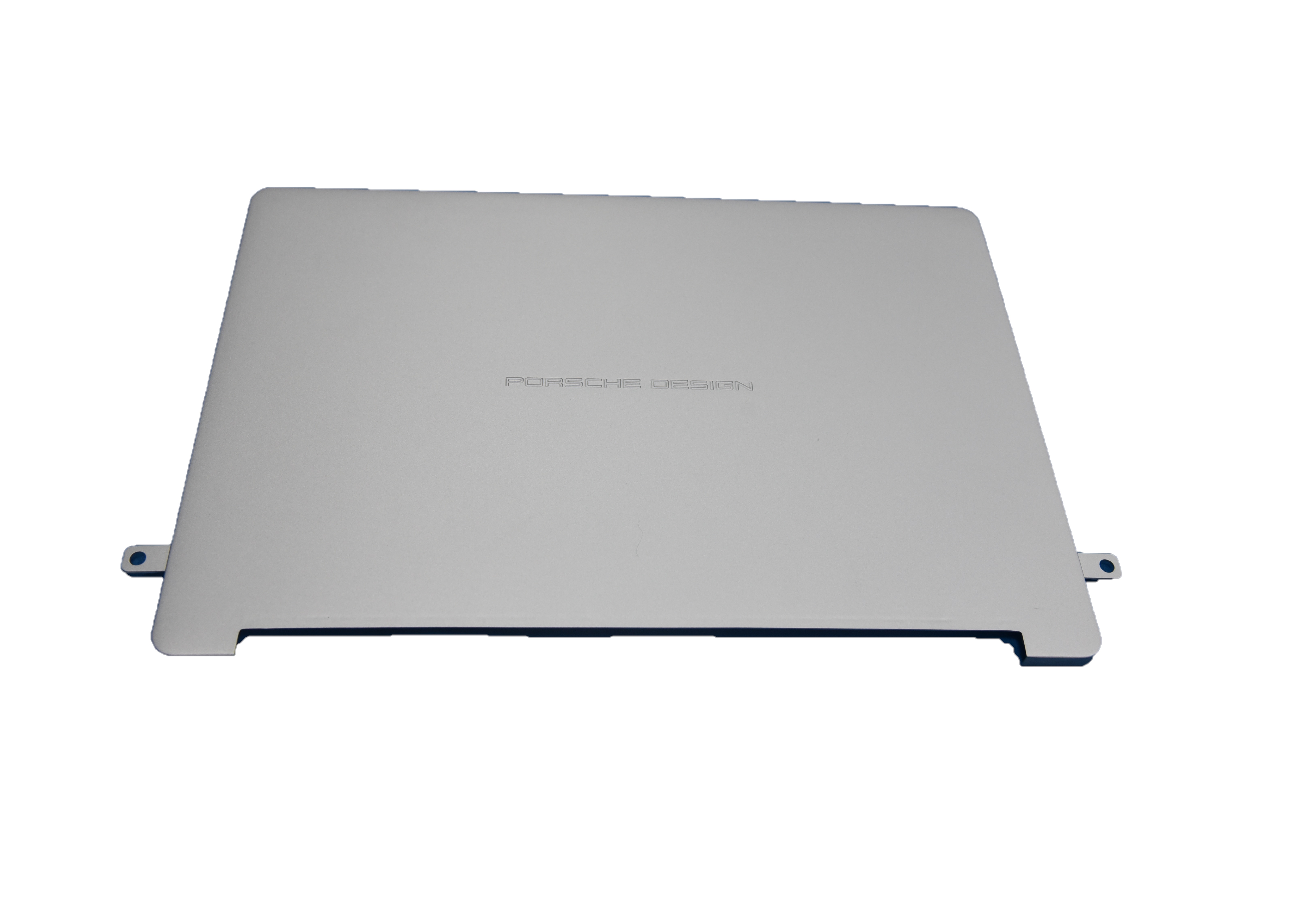

The standard configuration for business people is a laptop and a mobile phone, so that they can handle their business in a timely manner anywhere. But the laptop is too cumbersome, which brings a great burden to the person who carries it. Even people who go out often think that they can not bring them. But many metal notebooks on the market now look very large, but they are not very heavy in the hand. Because the entire shell is made of lightweight high-precision magnesium alloy, thixotropic injection molding refers to the process of injection and die-casting in the mold at the same time, forming an integrated molding mode. As a result, a whole notebook case is created, so now we can see that many metal products do not have welding, because the high-tech die-casting process can achieve integrated molding during manufacturing, which solves many manufacturing problems.

The weight of magnesium is light, so the lightness of magnesium can be effectively used to realize the characteristics of low density and light weight of the metal material in the process of using magnesium alloy. Therefore, in the current market, many metal products will not have a bulky effect. And the high-precision magnesium thixomolding notebook computer shell substitutes the concept of lightness into market sales, realizing the travel needs of consumers, and also bringing new contributions to the development of the electronic information industry.

-

- Magnesium alloy Thixomolding power batter housing

-

- OEM Die casting manufacturer produce magnesium alloy auto dashboard

-

- Magnesium alloy die-casting LED display frame

-

- Mangensium alloy die-casting Thixomolding metal parts

-

- Magnesium alloy die-casting rigid fork for bike

-

- Magnesium alloy thixomolding die-casting UAV parts

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com