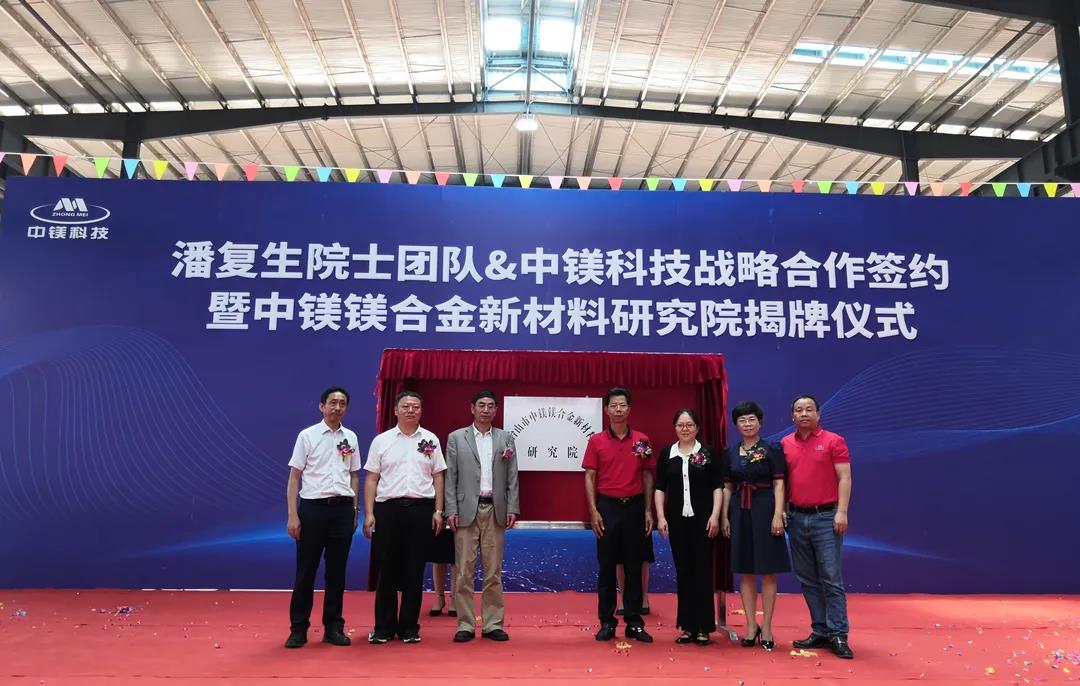

2021-4-30

Taishan Zhongmei Technology. Co., Ltd. jointly with the global leading expert Prof. Pan Fusheng of Chongqing University and his team, established Research Institute of Magnesium Alloy Materials. The signing and unveilling ceremony was held in Taishan Zhongmei ceremoniously on 2021-4-30. between three parties:

–Taishan Zhongmei Technology. Co., Ltd

— National Magnesium Alloy Engineering Technology Research Center of Chongqing university

— New Materials Research Institute of Guangdong Academy of Science

According to the agreement, to promote the technical cooperation & product development, accelerate the industrialization and large-scale application of technical achievements, the three parties have reached a strategic agreement to strengthen the cooperation on magnesium alloy materials R&D,application and industry, aiming to build a new magnesium alloy material base in Guangdong-Hongkong-Macao GBA

National Magnesium Alloy Engineering Technology Research Center of Chongqing university is a national base specializing in technological innovation and achievement transformation of magnesium alloy materials

New Materials Research Institute of Guangdong Academy of Science is one of the top 30 scientific research institutes in China. It has strong strength and remarkable achievements in nonferrous metals, powder metallurgy and composite materials.

Taishan Zhongmei Technology. Co., Ltd is a high-tech enterprise who focuses on the R & D and application of magnesium alloy materials. with full industry chain including full industry chain including Material Research, Tooling Design and Fabrication, HPDC, Thixomolding and Squeeze casting, CNC machining, surface treatment, Inspection and Testing. Owns 6 six large workshops and one R&D centre totally in 120000 square meters with annual capacity of 50000 tons. Totally over 300 personnel, of which 70 are engineering and Technical staffs.

-

- Magnesium alloy die-casting Auto parts controller housing

-

- Ultralight suspension fork for MTB

-

- Factory Custom China Bmx Cycles Road Sport Kids Bicycle 12 16 18 20 Inches Cycle Mtb For Kids 6-10 Year

-

- Magnesium alloy thixomolding die-casting UAV parts

-

- OEM high pressure die casting magnesium alloy wheel for e-bike

-

- Magnesium Aluminium alloy die casting parts Chain cover for automotive

0086-750-5616188

0086-750-5616188 +86 13392089688

+86 13392089688 sales@zhongmei-tech.com

sales@zhongmei-tech.com